- No results found

- Use cases

- Co-Creation Space

Community

Organizations

Collaboration Partners

- Login

NOT REGISTERED YET?

Register for the Use Case Management Service for free to start creating your first use case.

Registered users can use the download area and the comment functions.

All documents are licensed as a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License

(Attribution-Non-Commercial-ShareAlike 4.0). Further information can be found at

![]()

The documents reflect the current best practice and do not claim to be complete. They should not to be understood in the sense of a generally valid recommendation or guideline from a legal point of view. The documents are intended to support appointing and appointed parties in the application of the BIM method. The documents must be adapted to the specific project requirements in each case. The examples listed do not claim to be complete. Its information is based on findings from practical experience and is accordingly to be understood as best practice and not universally applicable. Since we are in a phase in which definitions are only emerging, the publisher cannot guarantee the correctness of individual contents.

The ROS BIM Integration project explores the dynamic integration between the Robotic Operating System (ROS) and the IfcOWL ontology, focusing on the automation of digital fabrication using Industry Foundation Classes (IFC) model data.

Aims:

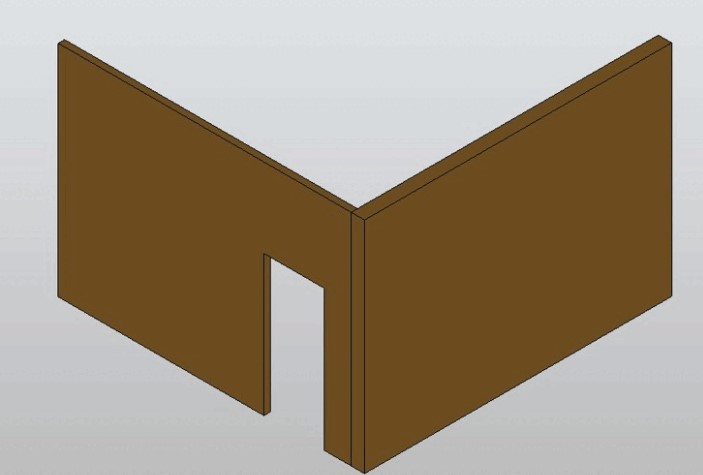

Align As-Built and As-Planned Models: The primary objective is to minimize discrepancies between as-built and as-planned models, improving efficiency and accuracy in construction, with a focus on gypsum board cutting.

Automate Processes: An integral part of the project is to streamline the construction process by integrating advanced technologies such as robotics, BIM, and ifcOWL ontology, leading to automation in digital fabrication and, initially, in gypsum board cutting.

Enable Interoperability with openBIM: The project aims to emphasize and harness the interoperability of openBIM standards, demonstrating how it can contribute to more efficient and streamlined digital fabrication processes, while maintaining flexibility and adaptability to meet varied construction demands.

Scope:

The current scope of this project is focused on automating the gypsum board cutting process through a fusion of robotics, BIM technology, and ifcOWL ontology. However, the inherent interoperability of openBIM standards and the flexibility provided by the use of ontologies, means this approach can be extended to other construction processes as per demand, without significant changes. This highlights the adaptability and potential future application of this technology in the broader construction industry.

The construction industry is undergoing a paradigm shift towards digitalization, with increasing demands for efficient and streamlined processes. The integration of Building Information Modeling (BIM) and robotic systems offer the potential to revolutionize construction through automation and seamless coordination between digital design and fabrication. The ROS BIM Integration project aims to explore this potential by focusing on the cutting of gypsum boards as a prototype of the system and bridge the gap between As-Built and As-Planned models by enhancing efficiency in cutting process.

The ROS BIM Integration project highlights the relevance of openBIM in the context of construction automation. By leveraging the interoperability and data exchange capabilities of openBIM, the project showcases how digital fabrication can potentially be streamlined and automated using IFC model data, contributing to more efficient digital fabrication processes in the context of construction.

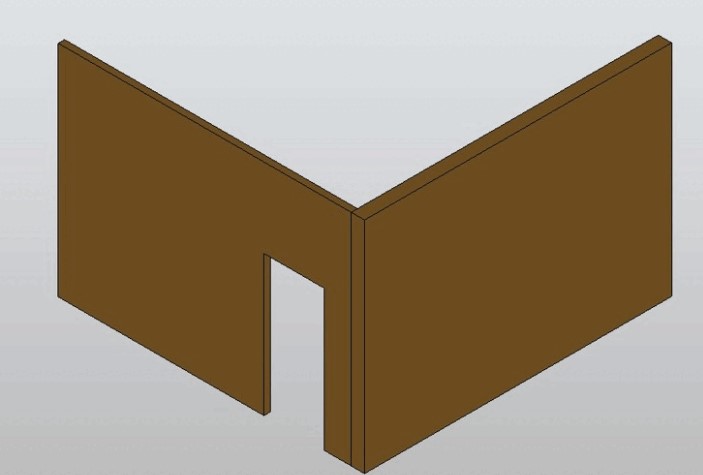

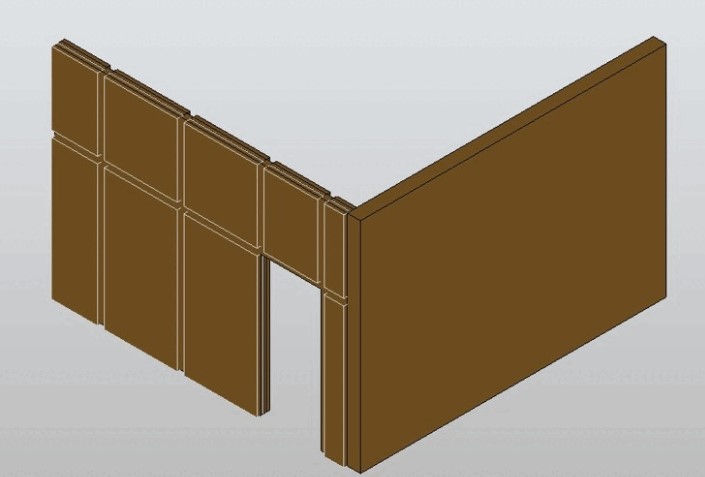

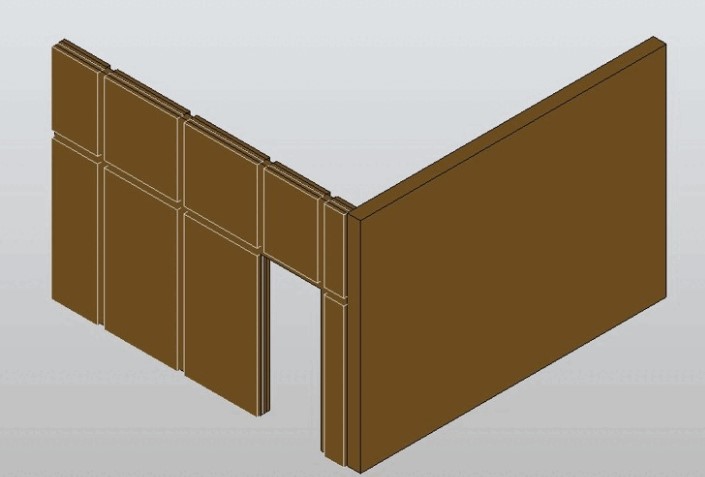

Geometry Processing:

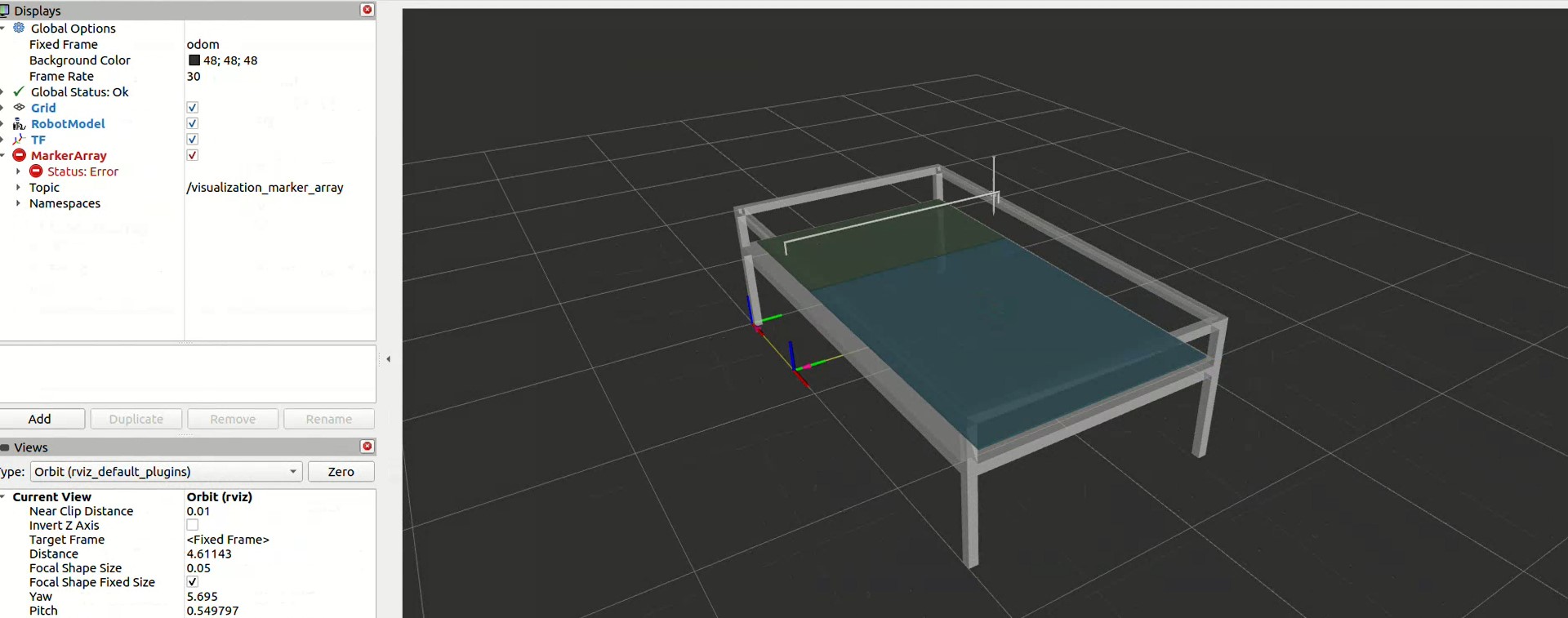

Slicing Gypsum Board with Robotic Operating System (ROS):

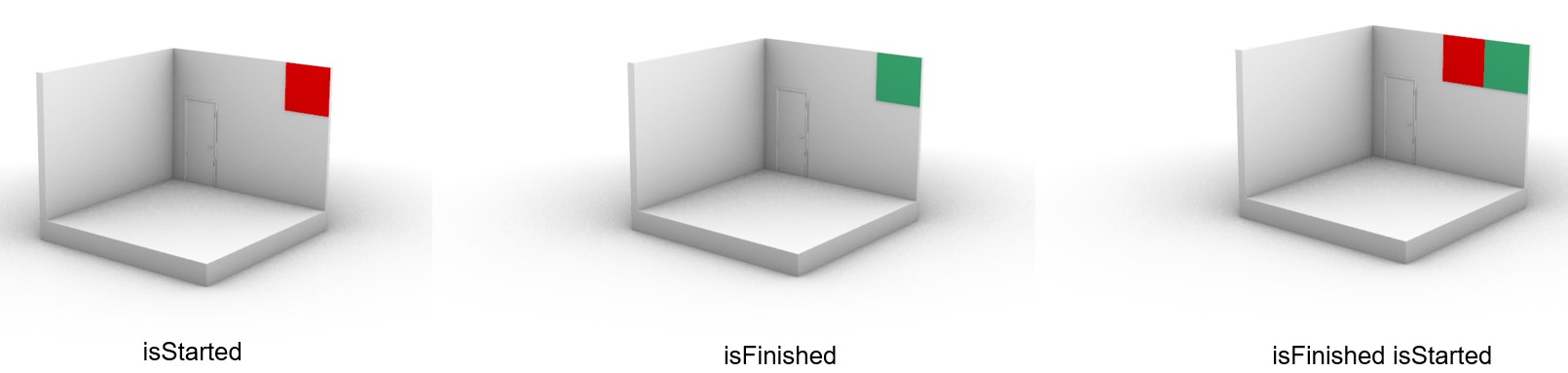

Real-Time Process Visualization with Grasshopper:

Upon commencing this project, our ambitious objectives sought to innovate the construction process through digital automation and interoperability. We've made significant strides, successfully integrating intricate systems. Though our objectives have been met and our prototype functions effectively, we recognize there's still room for enhancement and growth. This realization reflects our commitment to continuous improvement and innovation in the construction industry.

Objectives of Project:

Efficient Integration: The primary objective is to effectively integrate ROS with ifcOWL ontology and IFC model data, overcoming the complexities of these systems.

Establish Reliable Data Extraction and Processing: The project aims to develop a robust workflow for extracting and panelizing wall geometry data from IFC models, ensuring accuracy and consistency.

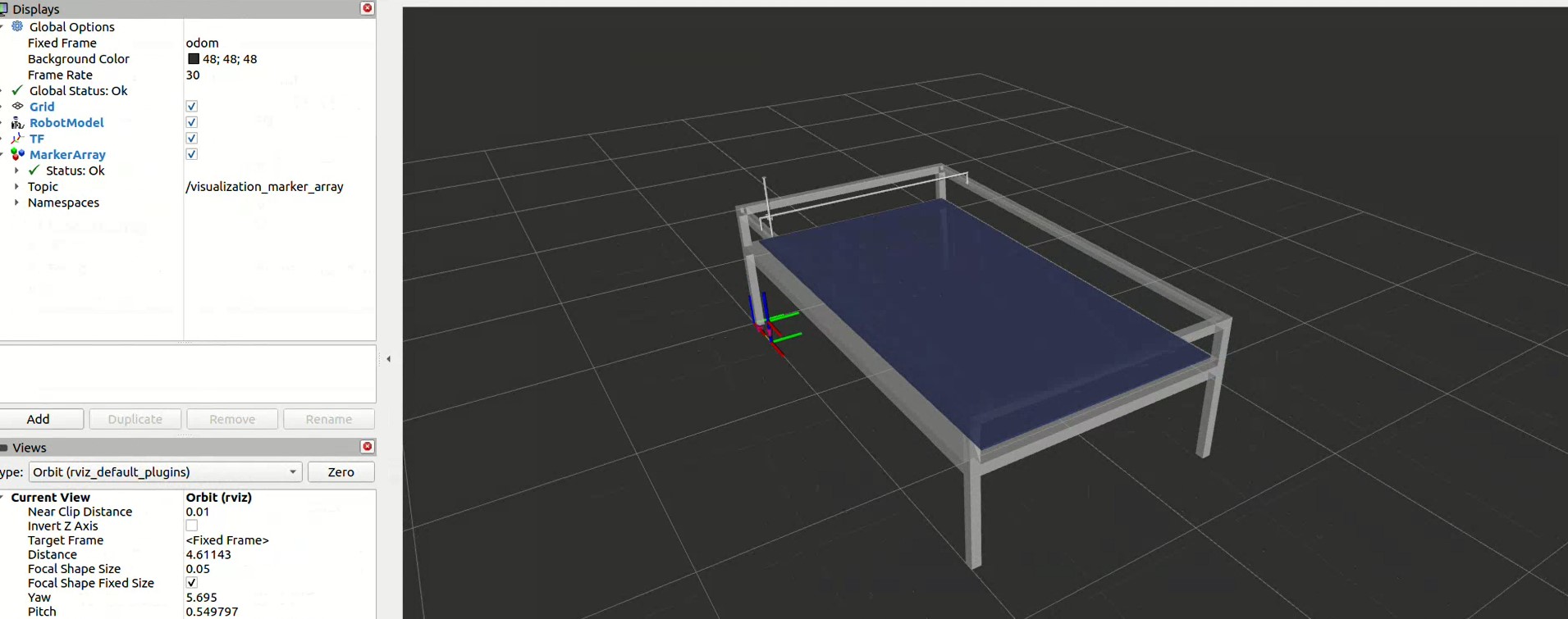

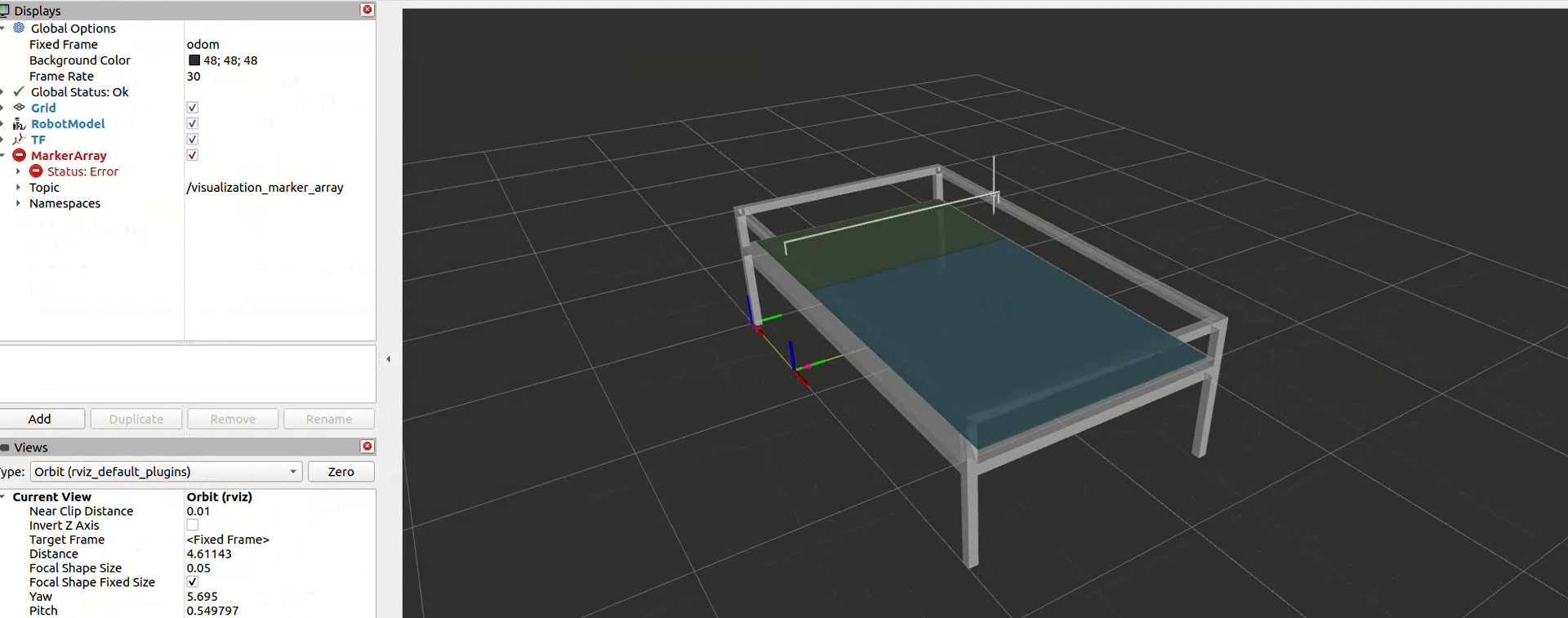

Develop Simulation and Visualization Methods: The project seeks to create methods for simulating and visualizing robotic movements and fabrication processes, integrating with tools like RVIZ for real-time feedback and adjustments.

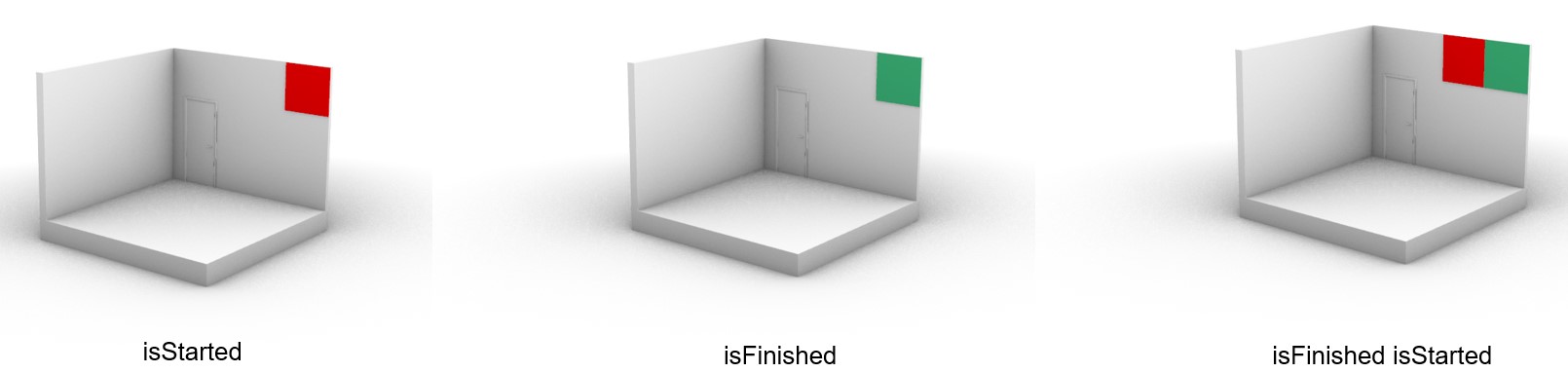

Ensure Synchronization and Updates: A key objective is to create a system that synchronizes the IFC model data with the fabrication process, updating the panel geometry and fabrication status on the server accurately.

Ensure Scalability and Flexibility: The project aims to create a solution adaptable to various fabrication tasks beyond gypsum board cutting, indicating its scalability and flexibility.

Plan for Future Improvements: Lastly, the project aims to identify potential areas for further research, development, and collaborations, considering the application of the solution in real-world scenarios.

Numerous past attempts to automate digital fabrication in construction by integrating BIM and robotic systems have encountered various limitations:

Dependency on Ontology & Semantic Web: Our methodology heavily relies on ontology, specifically, the IFC model being converted to ifcOWL. While there is a Github repository available for this conversion, this dependence is a limitation.

Restricted Application: Initially, our method was specifically applied for gypsum board cutting. Although it possesses scalability, its application beyond this remains to be explored. However, the potential for the project to be extended exists, and gypsum board cutting merely represents the initial stage.

Limited Ontology and SPARQL Expertise: The project utilizes the SPARQL query method and ontology, a combination that's not commonly used in the industry, resulting in a shortage of experts. While this is a current limitation, the rising popularity of ontology due to its data integration capability suggests that this approach will be increasingly suitable soon.

To successfully initiate and implement this use case, the following competencies are prerequisites:

Proficiency in Programming: The necessary scripts and related documentation are accessible via our Github repository. However, the successful configuration and deployment of these libraries necessitate a substantial level of coding proficiency.

Familiarity with Ontology: In the event that expansion of this method is desired, an in-depth understanding of ontology is indispensable. This knowledge domain is critical for facilitating the method's scalability and adaptability.

Expertise in Machine Operations and Robotic Programming: The installation and calibration of the cutting machine, and its subsequent integration into our script, require a high level of skill in both machinery operation and robot coding. These technical competencies are essential to the successful execution of the project.

The project utilizes a web server to facilitate data exchange, employing Python as the programming language to enable seamless data retrieval and submission. This is accomplished through the utilization of SPARQL queries and ontological concepts, which enhance interoperability and enable efficient data synchronization. The extraction of wall geometry and the dimensions of associated opening elements is performed using the Python OpenCascade (PyOCC) library, ensuring accurate and precise calculations. The Robot Operating System (ROS) is leveraged to execute robotic operations based on the dimension data obtained. The project emphasizes the use of interoperable formats, including various openBIM formats such as IfcOWL, which enhances data exchange capabilities and promotes collaboration among different stakeholders in the construction industry.

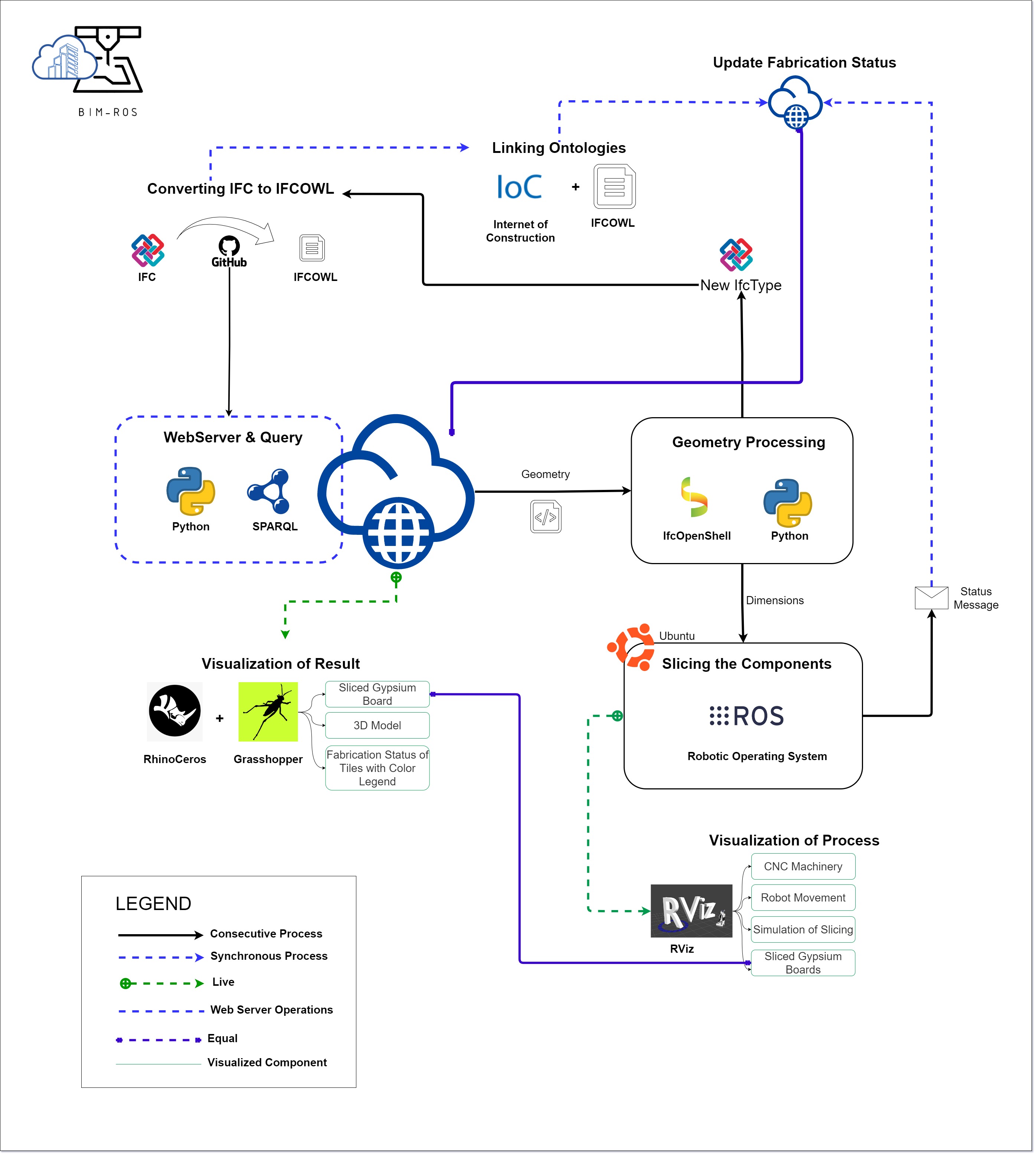

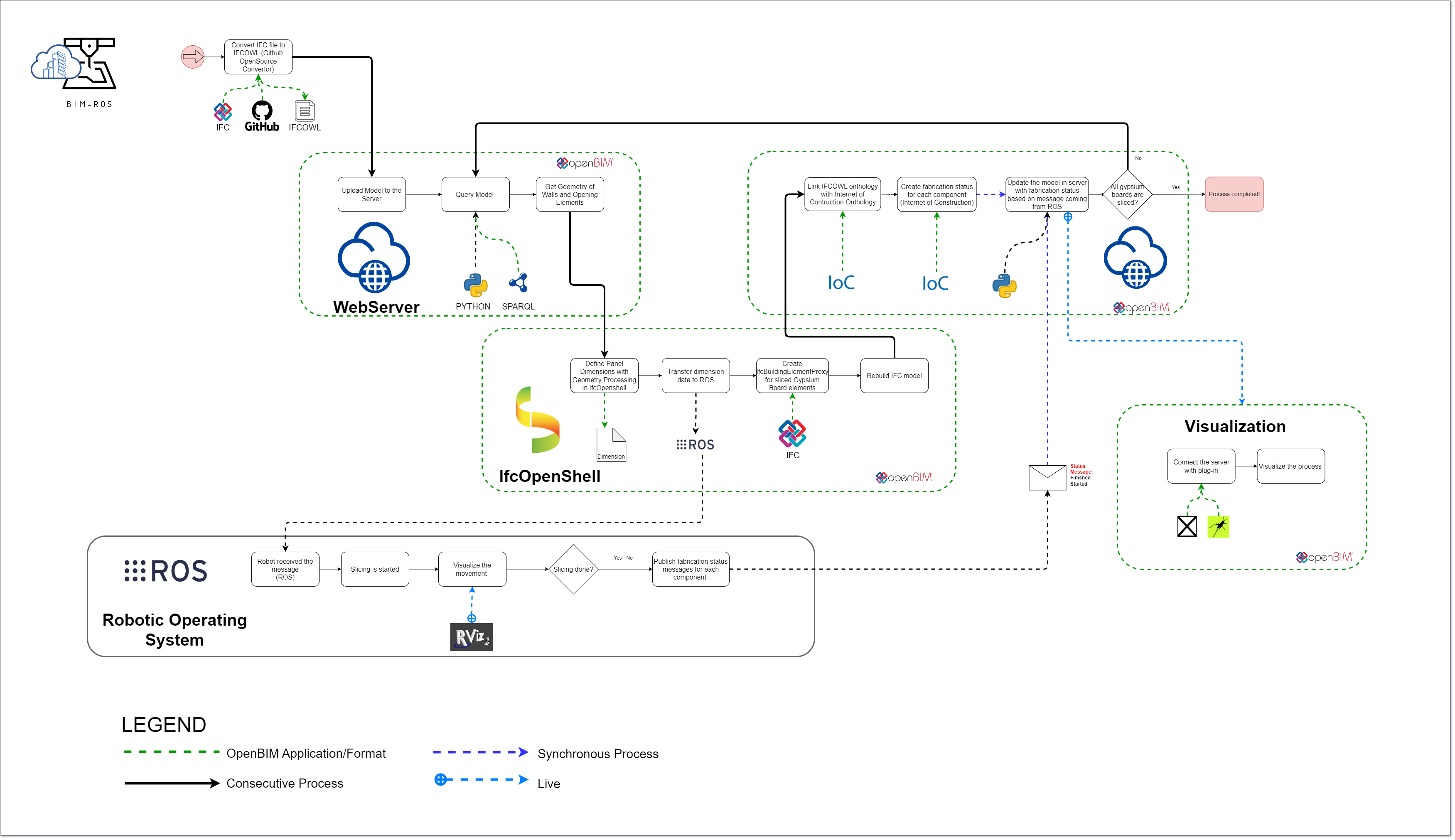

Software Ecosystem Map:

To review in higher quality please check the attachments

LOIN is indicated to show information and geometrical requirements of different formats.

Process Overview:

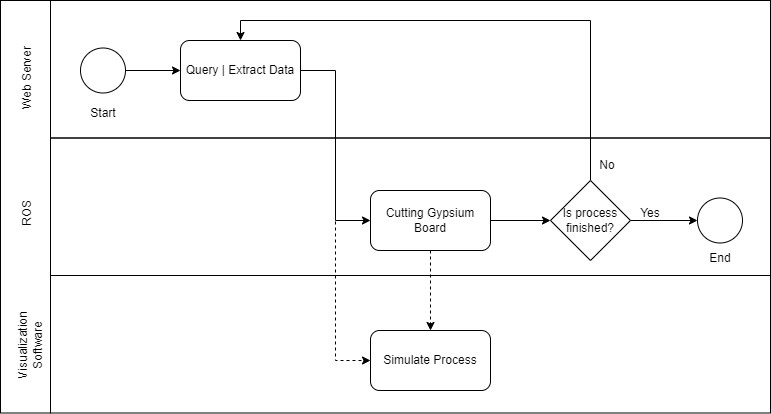

Process Map:

To review in higher quality please check the attachments

Steps

1 | The extraction of wall geometry and the dimensions of associated opening elements is performed using the Python OpenCascade (PyOCC) library:

2 | The Robot Operating System (ROS) is leveraged to execute robotic operations based on the dimension data obtained:

When robot received dimensions from server:

When slicing process is completed:

3 | Grasshopper visualize the process in real time:

The project, which is scalable and applicable in various locations, undergoes a brief stage and a design stage. For the gypsum board slicing process, the project is currently in between design and brief phases. For alternative approaches, comprehensive planning and defining goals, scope, and deliverables are necessary

BIM Implementation Strategy: Define the project's objectives, scope, and desired outcomes for incorporating BIM. Determine how different openBIM formats and softwares will be used throughout the project life cycle. Align the strategy with project goals, ensuring smooth collaboration, interoperability, and data exchange between software platforms.

Data Management and Integration: Establish protocols for organizing, controlling versions, and sharing data among project participants. Integrate BIM data with other project management systems using web servers and openBIM formats/software to ensure smooth collaboration and information flow.

Training and Support: Plan for training programs and support mechanisms to enhance the BIM capabilities. Ensure that team members have the necessary skills and knowledge to effectively utilize tools and workflows.

The gypsum board slicing process is designed, and scripts are created to achieve a seamless connection between software and integration of various data sources. To implement the project, machine operators need to set up and calibrate the system. The project follows a scalable approach, allowing for its application in different contexts. For the project to be utilized for various purposes, the project team should have the ability to use the necessary programs.

Proficiency in Programming: During the design stage, it is essential to ensure a sufficient level of coding proficiency for successful configuration and deployment of the necessary scripts and libraries. Access to the required scripts and related documentation can be obtained from our Github repository. This proficiency will enable effective utilization of the libraries in the design process.

Expertise in Machine Operations and Robotic Programming: Machine operators are responsible for setting up and calibrating the machines in their designated locations. Additionally, they should possess the necessary skills to troubleshoot and resolve any issues that may arise during operation.

Training and Support: Incorporate comprehensive training programs to mitigate the risk of failures. Ensure that team members acquire the essential skills and knowledge to proficiently utilize tools and workflows, resulting in effective project execution.