- No results found

- Use cases

- Co-Creation Space

Community

Organizations

Collaboration Partners

- Login

Video Use Case «Model-based layout of reinforcement»

Source Bauen digital Schweiz / buildingSMART Switzerland

NOT REGISTERED YET?

Register for the Use Case Management Service for free to start creating your first use case.

Registered users can use the download area and the comment functions.

All dokuments are licensed as a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License

(Attribution-Non-Commercial-ShareAlike 4.0). Further information can be found at

![]()

The documents reflect the current best practice and do not claim to be complete. They should not to be understood in the sense of a generally valid recommendation or guideline from a legal point of view. The documents are intended to support appointing and appointed parties in the application of the BIM method. The documents must be adapted to the specific project requirements in each case. The examples listed do not claim to be complete. Its information is based on findings from practical experience and is accordingly to be understood as best practice and not universally applicable. Since we are in a phase in which definitions are only emerging, the publisher cannot guarantee the correctness of individual contents.

The use case defines the necessary requirements for the structured reinforcement design models and their information content. This enables the following points:

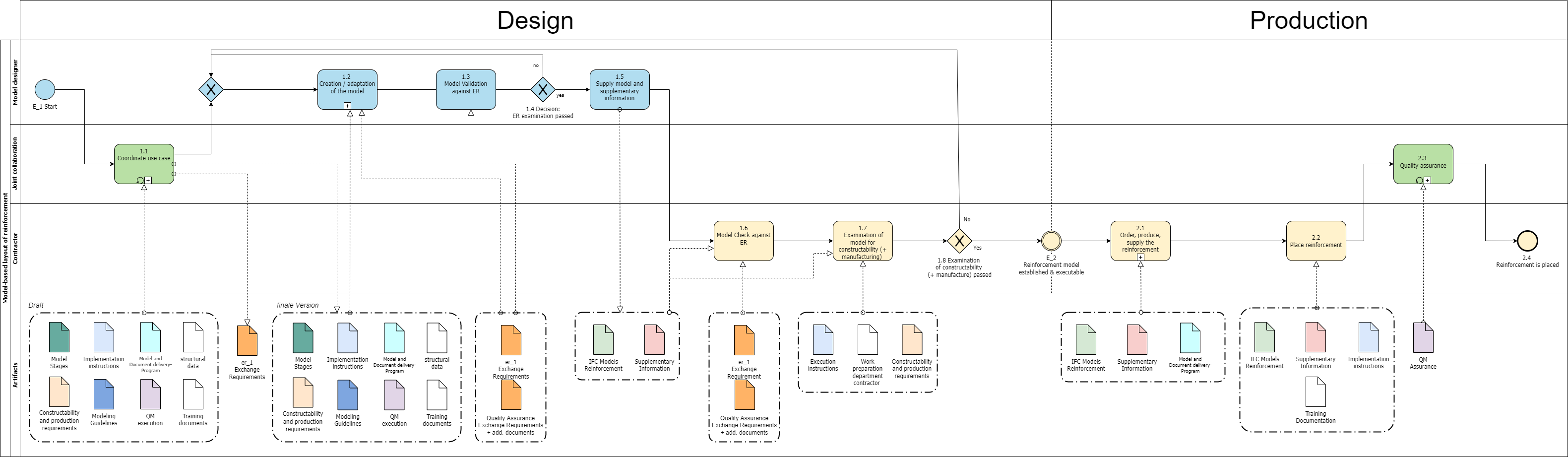

The use case «Model-based layout of reinforcement» describes the requirements and implementation for placing to be able to place reinforcement on the construction site from the execution model.

The following services support the use case «model-based layout of reinforcement»

MODEL CREATION, TESTING, DELIVERY AND USE ON CONSTRUCTION SITE

The quality and efficiency of modeling and data delivery are critical success factors for model designers (e.g., civil engineers) and performers (e.g., builders).

The success of a model-based construction site starts in the planning phase. The parametric execution model for cast-in-place concrete from Tekla already uses the standardized Exchange Requirements (ER) of the use case «model-based layout of reinforcement» and thus ensures the necessary IFC data quality.

This allows the model designer to concentrate on the optimal design and the executors on the construction. A data check is recommended if the model creator did not use the Exchange Requirements (ER) of the use case during modeling.

LEARN MORE (all information is available in German only)

BuildingPoint - UCM applications with Tekla and Trimble Connect

The Qualifier is a revolutionary, browser-based quality assurance program for BIM projects. It checks specific requirements for models and ensures data quality along the entire lifecycle. For more transparency, process reliability, precision and lower error rates in BIM projects.

LEARN MORE (all information is available in German only)

Singular Website: https://snglr.com/

Video: https://www.youtube.com/watch?v=lMtw8dvugu0

Qualifier-Link: https://app.snglr.com/

Login/E-Mail: ucm(at)buildingsmart.ch

Password: swissbau2022

With the BIM software Allplan, the model creator can generate the reinforcement models in the familiar environment and export them in an IFC- and Use Case compliant manner using integrated standard favorites. The attribute and export settings required for this were implemented according to the information requirements in this use case and can be used directly by the user. This ensures that the model and information quality of the execution data is guaranteed.

The reinforcement models are uploaded to the CDE platform (Bimplus) by the engineering office in accordance with the stages and made available to the master builder by means of approval. The reinforcement data can be freely compiled according to the user's wishes using attribute filters (sorting by stage, concreting section, location, etc.) and the reinforcement can be efficiently installed in this way.

LEARN MORE (all information is available in German only)

The 3D model should be created according to the following requirements:

Requirements Kickoff:

Hardware, software, training (kickoff process) should have been defined in the tender documentation and later fixed by all parties (e.g. planner, contractor, subcontractor).

Responsibilities and costs should be considered and incorporated into the plan

Initiator: Model designer

The model creator(s) and the executor(s) must have coordinated in recurring joint exchanges such that the following artifacts can be finalized based on the designs.

With this foundation, the model of the reinforcement can be created.

Responsibilities over the individual artifacts must be determined in advance. The CDE and the data storage is defined in the use case «Create execution model».

Initiator: Joint (model designer and contractor)

Initiator: Joint (model designer and contractor)

Executer: Joint (model designer and contractor)

Following artifacts are needed for process step 1.1 & 1.2 to implement the use case

Model Stages

The model from the use case «Staging and views of models» is to be used as the foundation for the model of the reinforcement. Included in this staged model are: All concrete elements incl.

their stages and concreting sections, both in geometric form and as information in the model.

Execution instructions

They define which points are to be observed during execution in addition to the information in the model, among others:

Contents of this document:

Model and document delivery program (delivery milestone)

It defines the time when which documents are needed to meet the construction schedule:

Content:

Work packages form the basis for the delivery of the:

Definition of work package:

The following points, among others, have a significant influence on the delivery time and must be clarified in advance by the contractor:

Structural data

The structural data is required for the creation of the reinforcement models. Ideally, structural engineers and model creators use consistent digital methods for the creation of reinforcement models (e.g., attributes for minimum reinforcement requirements, transfer parts of the reinforcement from structural analysis software to design software, ...). However, this is not mandatory for the use case. The specifications of the structural analysis contain among others

Buildability and production requirements

Modeling guidelines

see last chapter «Modeling Guidelines»

QM Execution

defines what must be observed during the acceptance of the installed reinforcement with regard to the model-based installation. These includes:

Schulungsunterlagen

For this purpose, the following issues must be trained respectively the knowledge must be available before starting the work:

Ideally, a checklist is used at the beginning to determine whether all project participants have the necessary knowledge – if necessary, the knowledge should be transferred through internal or external training.

Initiator: Model designer

In consideration of the coordinated use case and the associated bases / artifacts, the model designer creates or adapts the reinforcement.

Initiator: Model designer

Before the reinforcement is transferred as a model (.ifc), the model designer must check the following aspects must be checked against the exchange requirements. This should be implemented automatically.

er_1 Exchange Requirements

Quality assurance Exchange Requirements + other documents

The QM rules define which checks are undertaken to ensure that all documents are complete and plausible. These are among others:

Initiator: Model designer

Decision whether the quality gate for the exchange requirements has been passed and the model can be delivered.

Initiator: Model designer

The models (.ifc) and the supplementary information must be made available on a CDE (Common Data Environment) to the contractor. The transfer must be communicated to the contractor.

IFC reinforcement models

IFC reinforcement models (and concrete and built -in parts) are supplied by the model designer for each work package The following points, among others, must be considered:

--> Reinforcement / Sep. concrete + installation parts as reference

Supplementary information

The supplementary information supplied by the model designer (e.g. order lists, additional

execution instructions) are implemented according to specifications, checked and delivered per work package. The following points are to be considered, among others:

Initiator: Model designer

When receiving the reinforcement, the model (.ifc) must be checked by the contractor against the exchange requirements. This should be implemented automatically.

er_1 Exchange Requirements

see chapter «er_1 Exchange Requirements»

Quality assurance Exchange Requirements + other documents

The QM rules define which checks are undertaken to ensure that all documents are complete and plausible. These are among others:

Initiator: Model designer

The reinforcement model shall be checked for buildability and fabrication taking into account the execution instructions, the work preparation department of the executor and the buildability requirements.

Execution instructions

The final version of the execution instructions shall be applied.

Work preparation department of the contractor

Preparing the execution on the construction site from the model.

Constructability and production requirements

Apply the final version of the constructability and production requirements.

Initiator: Contractor

Initiator: Contractor

The reinforcement model has been created, tested and delivered and can now be used for the production / placement.

Initiator: Contractor

The reinforcement model has been created, tested and delivered and can now be used for the production / placement.

Initiator: Contractor

IFC reinforcement model with the supplementary information shall be provided to the manufacturer for timely delivery.

Initiator: Contractor

Taking into consideration the execution instructions, the IFC model of the reinforcement must be placed.

Training documents must be observed.

Initiator: Contractor

Quality assurance for the installed reinforcement is conducted on the basis of the defined QM rules and the associated responsibilities.

If necessary, the reinforcement must be corrected and finally documented (further use case) so that the reality corresponds to the model.

Initiator: Contractor

End of the process. Next stage / section can be implemented.

Initiator: Contractor