- No results found

- Use cases

- Co-Creation Space

Community

Organizations

Collaboration Partners

- Login

NOT REGISTERED YET?

Register for the Use Case Management Service for free to start creating your first use case.

Registered users can use the download area and the comment functions.

All documents are licensed as a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License

(Attribution-Non-Commercial-ShareAlike 4.0). Further information can be found at

![]()

The documents reflect the current best practice and do not claim to be complete. They should not to be understood in the sense of a generally valid recommendation or guideline from a legal point of view. The documents are intended to support appointing and appointed parties in the application of the BIM method. The documents must be adapted to the specific project requirements in each case. The examples listed do not claim to be complete. Its information is based on findings from practical experience and is accordingly to be understood as best practice and not universally applicable. Since we are in a phase in which definitions are only emerging, the publisher cannot guarantee the correctness of individual contents.

The Decommissioning to Reuse (D2R) Information Delivery Manual (IDM) supports the use of the Decommissioning and Reuse (DOR) BuildingSMART Data Dictionary (bSDD). The DOR bSDD enables model enrichment and streamlines information exchange necessary for maximising the reusability of buildings, products, components and materials throughout the following process:

· Pre-deconstruction Audit

· Deconstruction

· Material Bank Assessment

· Reuse

· Remanufacturing

· Inventory Management

· Preconstruction (Design for Reuse)

· Preconstruction (Design with Reusables)

· Building Design process incorporating digital material banks

The D2R IDM facilitates communication and information exchange among actors, information models and tools involved in these phases, promoting circular economy practices in construction.

Figure 1. The overview of processes supported in this UCM and DOR bSDD

Construction projects are resource-intensive, often leading to significant waste during the end-of-life (EoL) phase. The transition to a circular economy—moving from a take-make-waste model to a take-make-recover-transform-repeat approach—addresses issues of unsustainable resource use and waste generation. The Circular Economy aims to keep products in the value chain at the highest possible quality for as long as possible, reducing raw material usage, waste generation and carbon emissions. Kirchherr et al. (2017) conceptulised a cascade of circular actions to promote resource efficiency, conscious design and consumption, and prevent waste generation, as shown below.

Figure 2 The Circular Economy hierarchy, developed from Kirchherr et al. (2017)

Reusing a construction product after its life cycle ends is highly encouraged for two main reasons: it saves raw materials and reduces carbon emissions by eliminating the extraction and production phases in the second life cycle, which are particularly carbon and material-intensive. Since it is not always feasible to reuse an item exactly as it is after the EoL phase, a hierarchy of lesser circular possibilities has been established.

Reusing a product implies it is passed from one hand to another. Therefore, a novel mechanism in the circular construction supply chain is needed to connect the reclaimed, reusable pieces with potential buyers. This is where material banks, or marketplaces, come into play. Material banks link the end-of-life phases of a building component (e.g., deconstruction audit and deconstruction) to a new life cycle (e.g., design with reuse). They often serve as both physical locations for storing and reselling reusable construction products post-deconstruction and digital platforms to enhance the accessibility and visibility of available reusable materials and components. Additionally, they recertify the reusability of materials and components, ensuring they meet the required standards for new applications and possess adequate environmental, structural, and chemical performance. Having material banks, which serve as repositories of reusable items, facilitates reuse and thereby extends the lifecycle of building components.

Figure 3. Material banks interact with the parallel worlds of digital and physical workflows

DOR’s taxonomy is comprehensive, with logically interconnected classes and properties that allow for the development of chain axioms.These axioms are elaborated to avoid binary dead-ends and encourage detailed elaboration of circular information requirements. The novelty of DOR is to avoid binary dead-ends and enable a machine-readable flexible, tailored and expandable chain axiom understandable by all circular actors. While the DOR bSDD and ontology list properties that ensure materials, products, components and buildings are circular, there is a need for guidelines on how and when to use these properties.

The D2R Information Delivery Manual (IDM) and Use Case Management (UCM) offer state-of-the-art workflows that ensure a product is designed for reuse or becomes reusable. D2R encompasses various processes, each capturing, consuming, or producing different circular-related information from DOR. Since not all actors and phases have the same information needs, the D2R process maps are designed to provide the right amount of circular information necessary for each operation but they also need to be communicated and passed by via material banks.

The DOR is influenced by ISO 19650-1. It aims to create a minimum vocabulary usable by both Project Information Models (PIM) and Asset Information Models (AIM); as such, DOR supports both existing assets (including reclaimed, reusable components) and new assets designed for deconstruction (and reuse in the future) through same standardised vocabularies. The D2R supports circualr construction in the absence and presence of a PIM or AIM. Many existing buildings and reclaimed products lack information models, a factor that has been considered in the process maps of the D2R.

The process maps are delivered following the interviews with circular construction experts. The interview questions were influenced by the ISO 29481 series to see what is examined when, with whom, and how. This step was intended to optimise and validate the DOR properties and provide process maps that support real-world applications.

The proposed bSDD is in perfect alignment with the Level of Information Need concept as outlined in the EN 17412-1:2020 standard (Building Information Modelling - Level of Information Need - Part 1: Concepts and principles). This alignment ensures that DOR provides a minimum set of circular construction vocabularies that serve the purpose and avoid redundancy, thereby complying with industry standards.

The project aligns with European and international standards for sustainability and circular economy, such as ISO 20887, ISO 21930, Product Circularity Data Sheet (PCDS, ISO 59040) and several European Commission's guidelines. The bSDD aims to create a minimum vocabulary for the circular economy, fostering a more objective and standardised approach to circular construction.

This DOR bSDD has a trans-perspective nature, meaning that different perspectives of reusability and circularity, which are currently subjective due to the infancy of the circular economy, can be modelled. The idea is to accommodate the diverse and evolving nature of the circular economy projects in the construction industry. To this aim, DOR's set of classes and properties make circular economy understanding and discourse more objective. This information helps to host many projects with the same capabilities for different groups of people in different countries. The present UCM and process maps support the trans-persepctive nature of the DOR.

The process maps and information exchange procedures have been well-received by both field practitioners and academics. After nearly six years of extensive multi-step research, this UCM provides a comprehensive guideline to ensure that relevant actors deliver the right information at the appropriate time, using standardised vocabularies and processes. This approach ensures the continued integration of circularity in current practices and helps future-proof information exchanges for long-term sustainability.

Following this use case enables users to correctly populate their information models and databases (such as reusable marketplaces) with the correct circular construction information. This use case supports nine processes related to circular construction. It also enables users to properly use DOR bSDD properties in their projects.

This use case relies on the Decommissioning and Reuse bsDD -or the Decommissioning and Reuse ontology if the users want to rely on the RDF format.

In various processes, different properties of the DOR are used, tailored to the specific information requirements of each process. Since circularity and circular construction depend on effectively transferring information to the next actor in the supply chain to enable reuse or other circular actions, some properties are developed for multiple phases and actors. This ensures that all necessary information is consistently available and usable throughout the lifecycle of a project or product.

The implementation of this D2R use case offers several BIM objectives and benefits:

Improved Information Integration: This UCM supports projects and actors interested in the seamless reintegration of circularity and EoL information across all stages of a project or product. By aligning with bSDD classes and properties, D2R ensures that actors can populate their information models with the correct data and make sense of the data they receive from their partners.

Supporting Circular Economy and End-of-Life Cycle-related Exchange Requirements: This UCM helps set up circular economy-related exchange requirements for nine different processes using the DOR bSDD. It also enables actors to independently set up their own information exchange requirements, following the process maps that outline how different processes can benefit from incorporating the appropriate properties into their models. This ensures efficient management of complex data requirements throughout the project lifecycle.

Support for BIM-based Marketplaces: By facilitating the exchange of circular information between BIM models and IFC/OpenBIM-based reusable marketplaces, the D2R process maps support (1) developing high-quality models and (2) setting up material bank systems compatible with BIM, enabling long-term sustainability within the built environment.

Compliance with International Standards: By aligning with ISO standards and European guidelines for sustainability, circular economy, and BIM, this use case ensures that projects follow recommended and recognised best practices. This adherence facilitates global compatibility and interoperability, which is crucial for supporting the reuse of products in circular construction.

Enhanced Transparency and Uniformity: The availability of this UCM and the exchange requirements it supports promote transparency and consistency in data exchange. By providing a common language and step-by-step process maps, the use case ensures uniformity in how information is interpreted and applied, which is crucial for effectively exchanging circular-related information among diverse platforms and actors.

Objective and Standardised Circular Economy Practices: The terminology and vocabulary provided by the bSDD empower practitioners—regardless of their expertise in the circular economy—to align with best practices. This standardisation helps reduce subjectivity and sets a foundation for harmonised approaches when it comes to marketplaces and material banks, ensuring long-term relevance and impact across all phases of a project.

Accessibility for Diverse Stakeholders: The open availability of this UCM ensures that actors across the circular construction supply chain, from large organisations to SMEs, benefit from standardised solutions. Whether integrating circular economy practices into existing workflows or adopting them for the first time, stakeholders have access to the same robust data dictionary and process flows, fostering the democratisation of circular construction practices.

Risk Reduction and Improved Collaboration: The DOR bSDD standardises information management, while the D2R UCM standardises processes. Together, they mitigate the risks of data inconsistencies and miscommunication. The D2R processes exhibit how the information created by one actor is used by one actor in subsequent phases or in another circular project. The D2R supports frictionless collaboration among stakeholders by ensuring that all parties have the minimum information required for their models, minimising any future absence of critical circularity or EoL data.

The scope of this project is limited to the design through reuse marketplaces and digital diagnosis of reusability (and other circular potentials) from end to end. Therefore, it does not encompass all terminology, classes and properties for all circular practices. For example, disassembly procedures are not modelled, or bio-based materials are not included yet.

|

D2R |

Decommissioning to Reuse |

|

DOR |

Decommissioning and Reuse |

|

EoL |

End-of-Life |

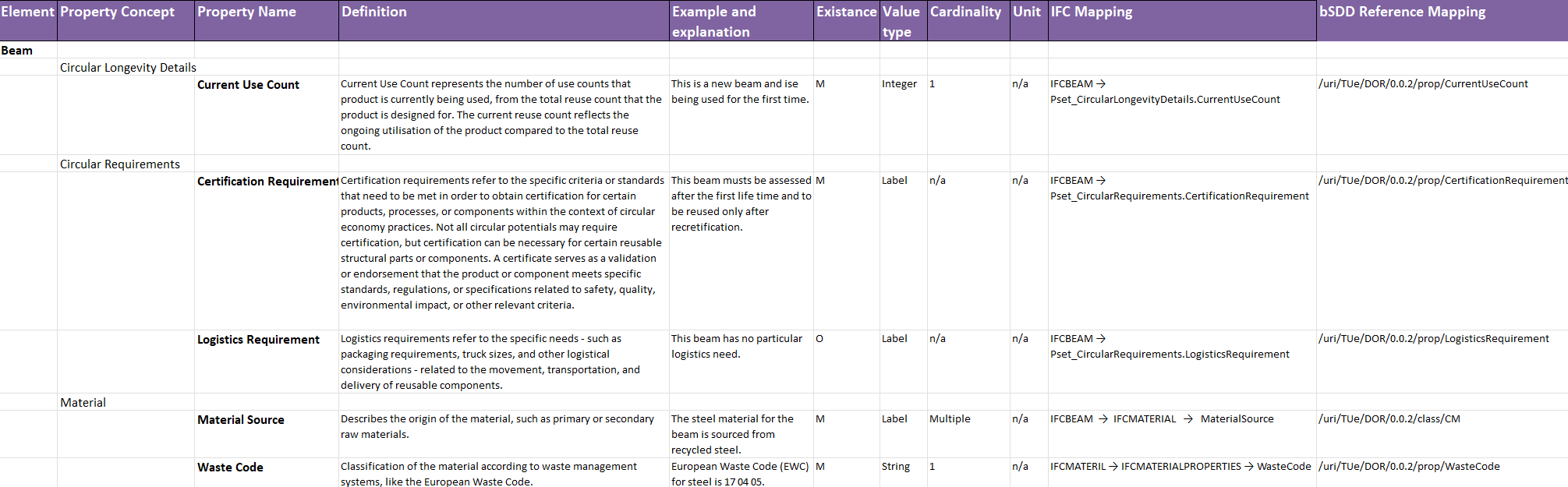

Table 2 outlines an example of an exchange requirement for a beam element in an assembly designed for reuse and decommissioning. Different ptoperty sets and properties that cover aspects of circular construction are showcased.

In this example, the information is categorised into Circular Longevity Details, which track the beam’s reuse cycles, and Circular Requirements, which specify essential requirements and considerations needed to ensure the beam’s proper End-of-Life (EoL) handling and reuse. Lastly, the Material section records the source type of the beam’s materials—while the material itself is steel, the source type is recycled steel—and its waste classification, supporting resource efficiency and promoting sustainable EoL practices. The product used in this example is elaborated in Fodor et al. (2023).

Table 2. Example of information exchange requirement supported by D2R UCM for a demountable and reusable construction product

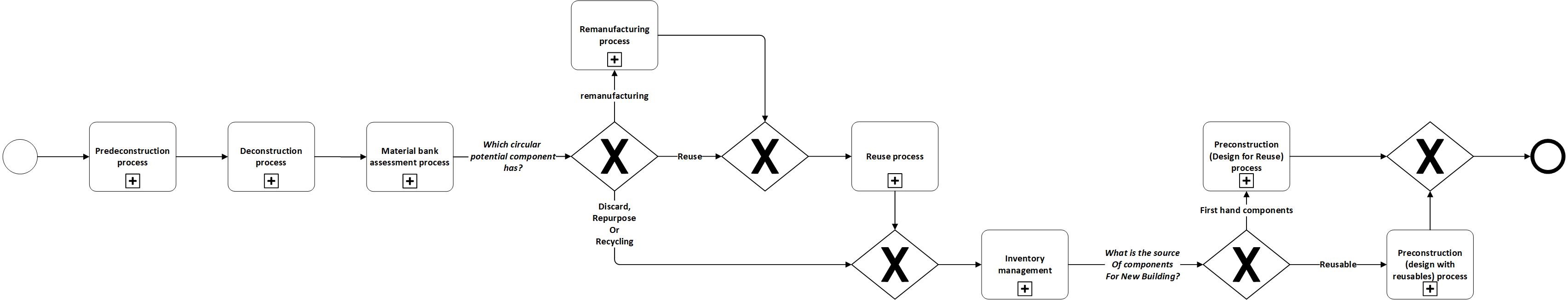

This use case consists of a High-level Diagram process map with nine processes:

Figure 4 illustrates the comprehensive range of processes supported by the Decommissioning to Reuse (D2R) process maps and the Decommissioning and Reuse (DOR) bSDD. In the rest of this section, the description of each process map is provided following its illustration.

Figure 4. High-level diagram of Decommissioning to Reuse (D2R) process maps

Figure 4. High-level diagram of Decommissioning to Reuse (D2R) process maps

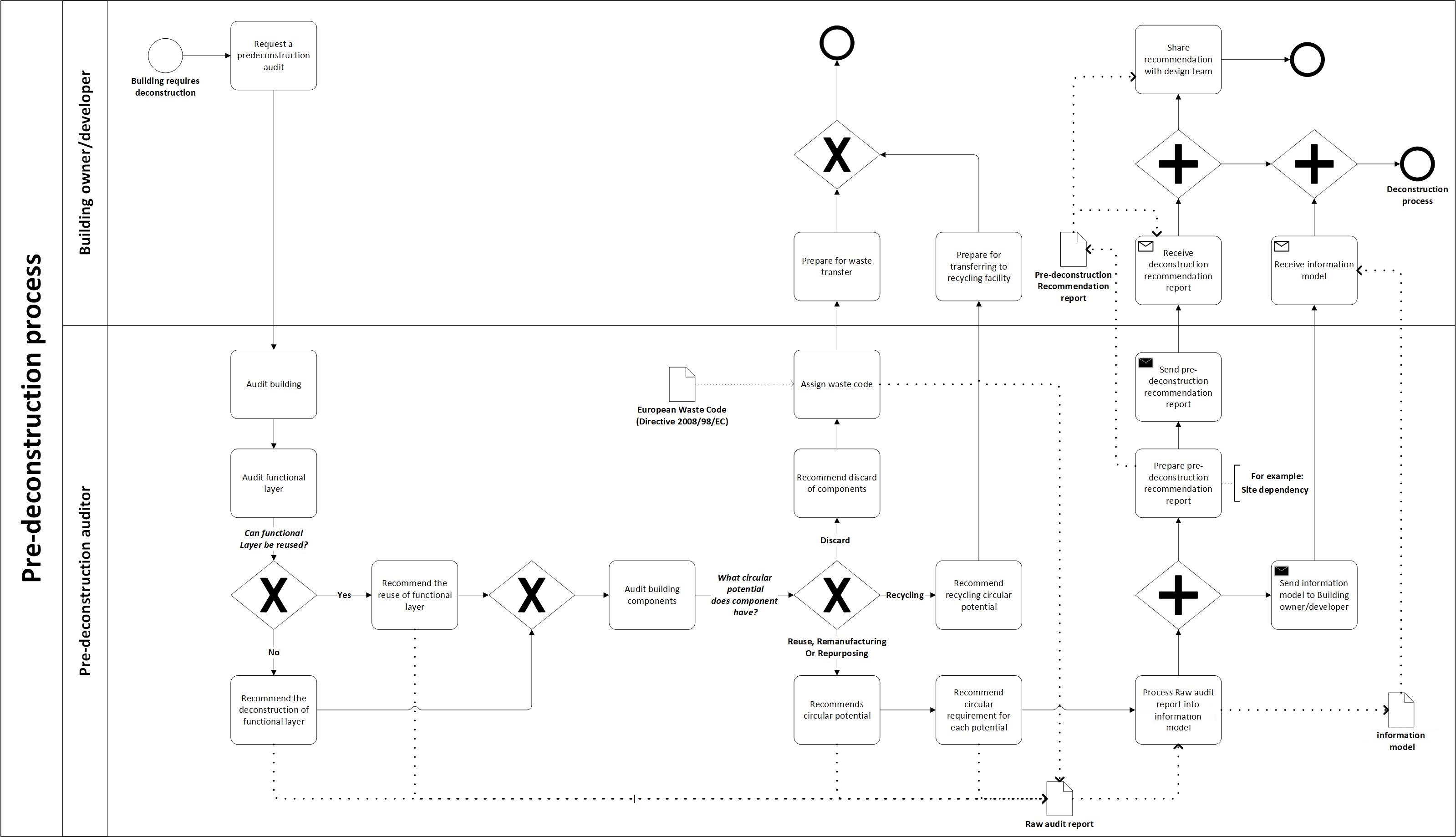

Figure 5 is the process map for Pre-deconstruction Process. It illustrates the pre-deconstruction process involving two stakeholders: pre-deconstruction auditors and building developers/owners. The process begins with the decision to decommission an asset, often initiated by a request from the building developer for a pre-deconstruction audit (also known as waste audit). A pre-deconstruction auditor is responsible for conducting an audit of the building. The assessment must be carried out to check the reusability of (1) functional layer, for example, structural layer or facade layer; (2) products or components, for example, false ceiling, door, windows, beams, and columns; (3) materials, for example, soil. The pre-deconstruction auditor can recommend reuse, remanufacturing, recycling or discard in the pre-deconstruction report. The decision-making process regarding functional layers must precede the audit of individual components. Components with potential for recycling but not reuse are prepared and sent to a recycling facility. If the overall quality of products is not promising, the pre-deconstruction auditor may recommend their disposal, assigning appropriate waste codes for proper waste handling.

Figure 5. Pre-deconstruction Process Map

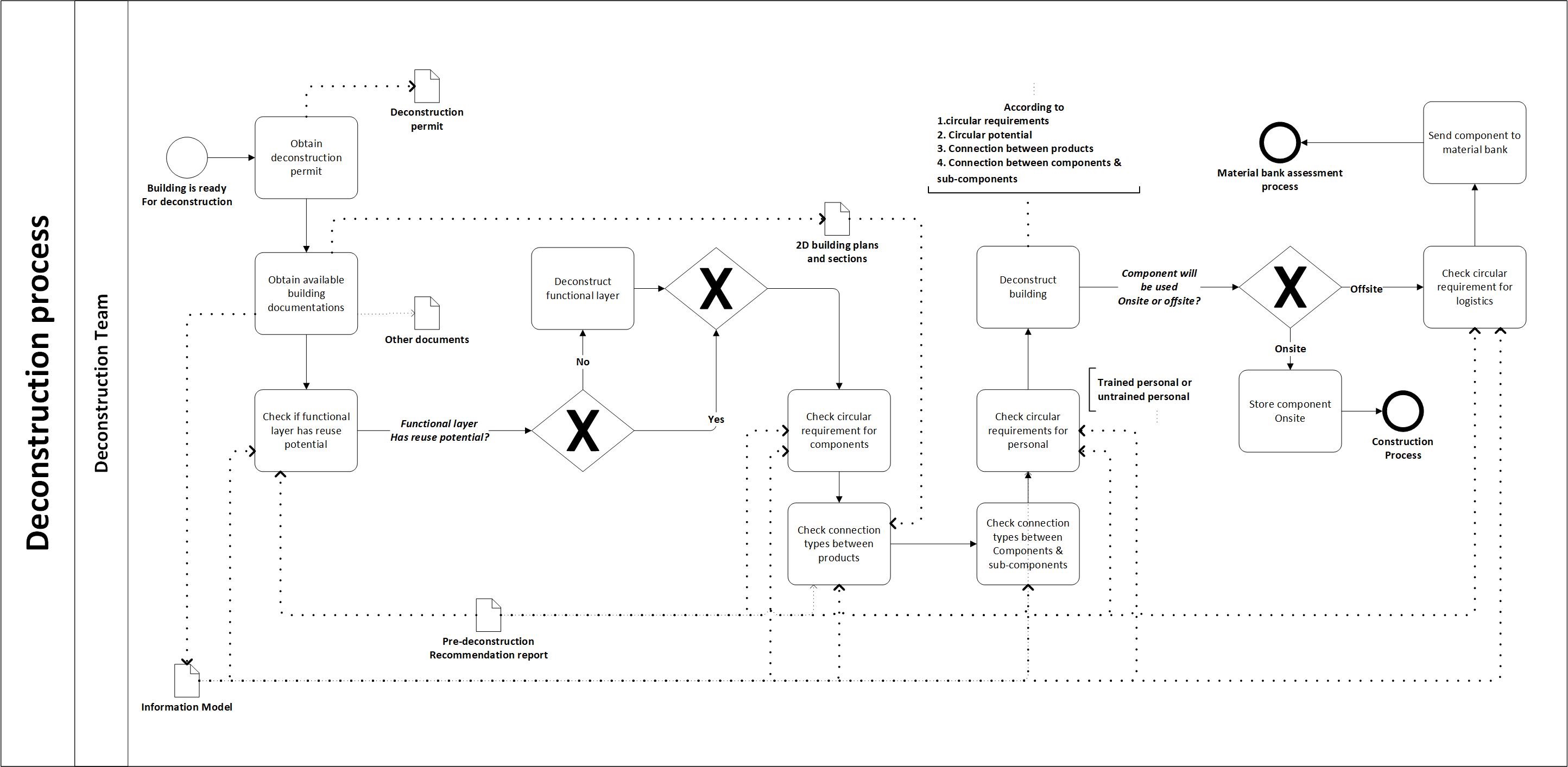

Figure 6 is the process map for Deconstruction Process. It shows the deconstruction process conducted by the Deconstruction team or decommissioning contractors. After obtaining the deconstruction permit, any document that supports safe deconstruction must be collected. Following the recommendations in the pre-deconstruction report, the deconstruction team checks the sequence based on which deconstruction must be carried out.

If it was decided to reuse a particular functional layer, the team identifies and removes components from the building that do not support that specific layer, taking into account any circular requirements that may exist. In fact, a critical task is removing products from the building. Prior to deconstruction, the circular (or end-of-life) requirements must be checked:

Finally, the deconstruction process concludes when the materials/components are sent to the material bank storage site. Health and safety regulations must be observed throughout the deconstruction phase, similar to conventional demolition projects.

Figure 6 Deconstruction Process Map

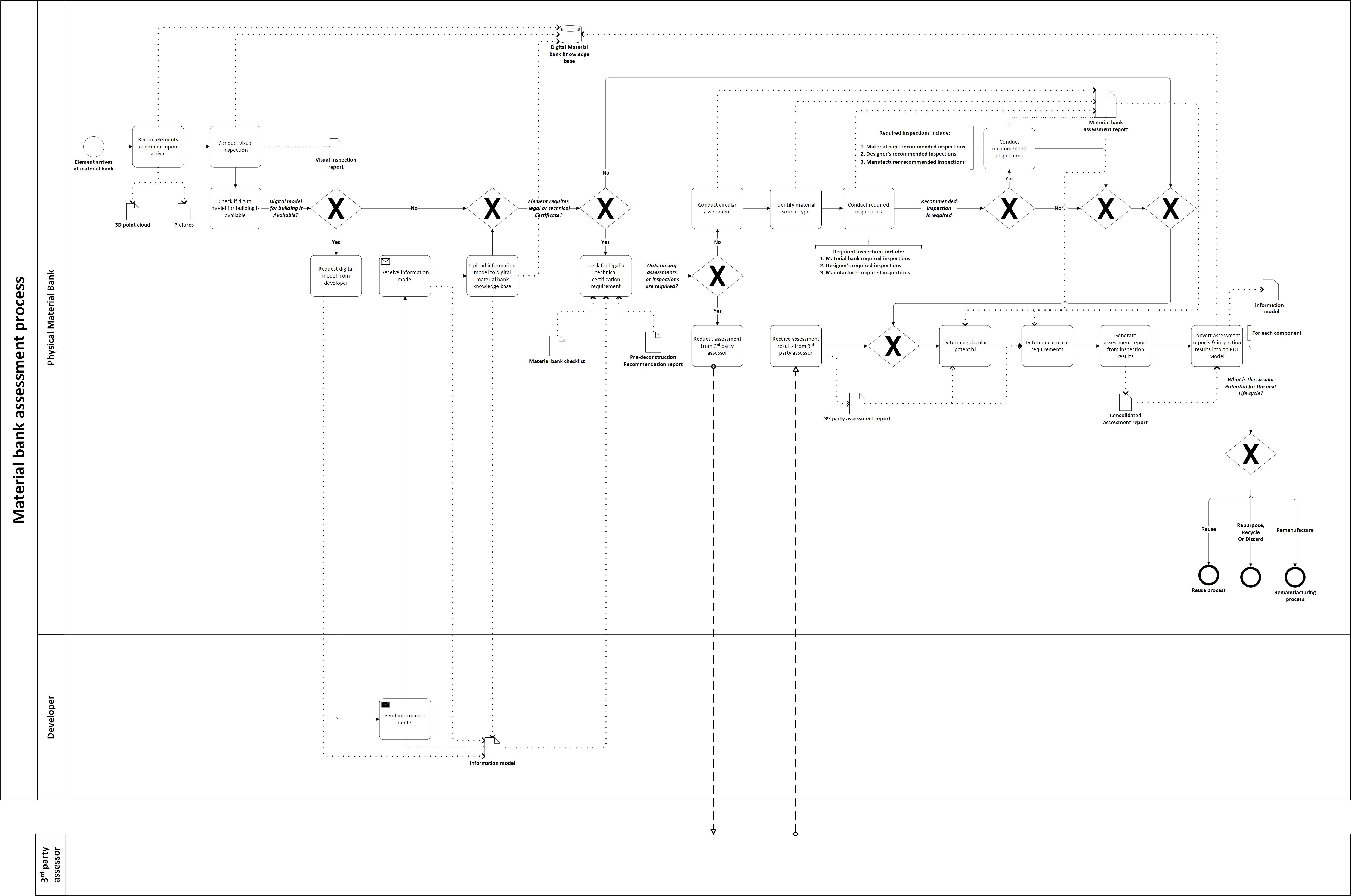

Figure 7 is the process map for Material Bank Assessment. It begins when a reclaimed element arrives at the material bank. At this stage, condition recording becomes necessary. Condition recording can be done through 3D capturing technologies or photographs. This recorded information is then communicated and integrated into the material bank database. More about internal procedures for capturing information are described in Akbarieh et al. (2021) and Akbarieh (2023).

After condition inspection and recording, the material bank database is examined to determine whether the elements have an existing object information model. If an information model is present for that reclaimed object, the material bank requests the building developer/manufacturer share it. After this phase, the information model is stored within the material bank database. Before proceeding with further assessment tasks, the first step involves checking for any legal or certification requirements applicable to each component.

The assessment process is relatively straightforward for components such as doors, which typically do not require extensive technical certification or legal/standard tests to confirm their chemical safety, environmental and structural performance. If certification is unnecessary for such components, the process continues by assessing their circular potential based on a visual inspection report. Additional circular requirements can be determined in subsequent steps, resulting in a consolidated assessment report in PDF format, XML, or other convertible OpenBIM formats. If the data format of the report is aligned with the OpenBIM schema, it is easier for the structured information to be stored in the digital material bank. Subsequently, the (re) generation of a downloadable information model to be communicated over the reusable material database interface could be automated.

Components requiring legal or certification requirements undergo a comprehensive assessment within the material bank. This step involves necessary inspections, including both required and recommended ones, and the component's inspection information and initial data model are checked against the knowledge base. Although the material bank conducts the inspections, third-party assessors such as technical laboratories can also perform them. This information can be communicated via “Certification Requirement” and “Legal Requirement” properties from DOR bSDD. In such cases, information is exchanged between the material bank and the third-party assessor. Once the material bank receives the assessment report, it is utilised to determine the circular potential, following a process similar to that of non-technical components.

The entire Material Bank Assessment process map concludes with three potential outcomes for the materials: reuse, remanufacture, or repurpose/recycle/discard. The first two outcomes - representing optimal circular potentials - are explained in further sub-processes below. Each of these circular assessment results can be added to any element via dedicated Circular Potentials.

Figure 7. Material Bank Assessment Process

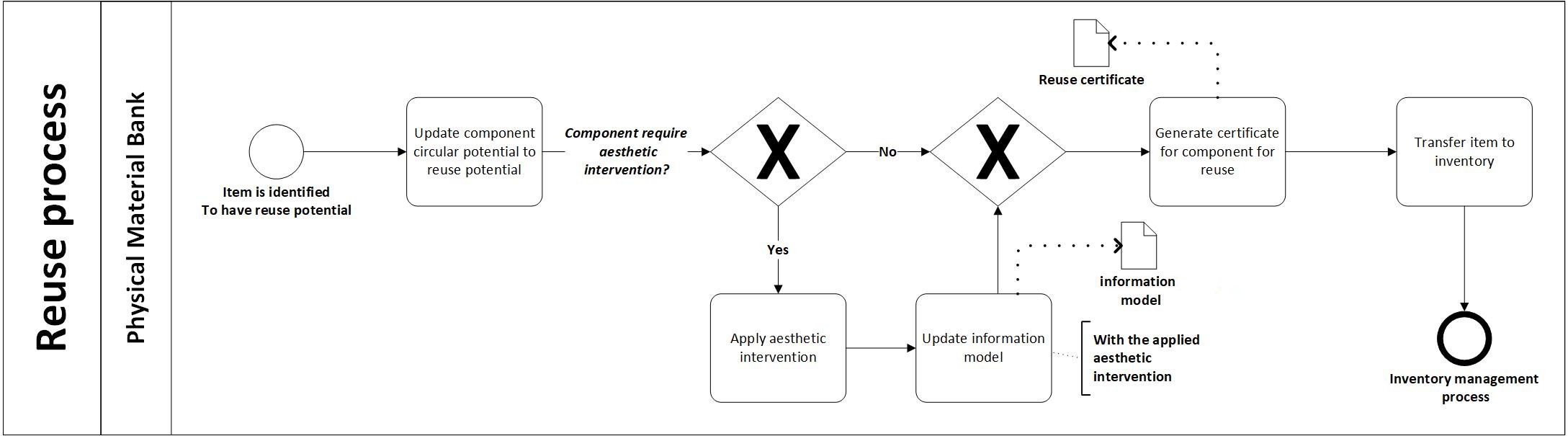

After the physical assessment is completed, if it is determined that a component can be reused, the reuse process can proceed according to Figure 8, the Reuse Process. In this case, the "Reuse Potential" can be added to the information model to communicate this decision. Initially, the database must record that the product's usability has been confirmed through tests. If minor aesthetic interventions are required, they will be implemented. The information model within the material bank interface is then updated accordingly, as certain actors may need to be aware of aesthetic alterations before making up their minds about purchasing or reusing that element. This information must be captured and utilised in the information models. A valid certificate will be issued once the reusable element is fully prepared for reintroduction into the value chain. Then, the item will be transferred to the inventory, marking the completion of the reuse process.

Figure 8. Reuse Process

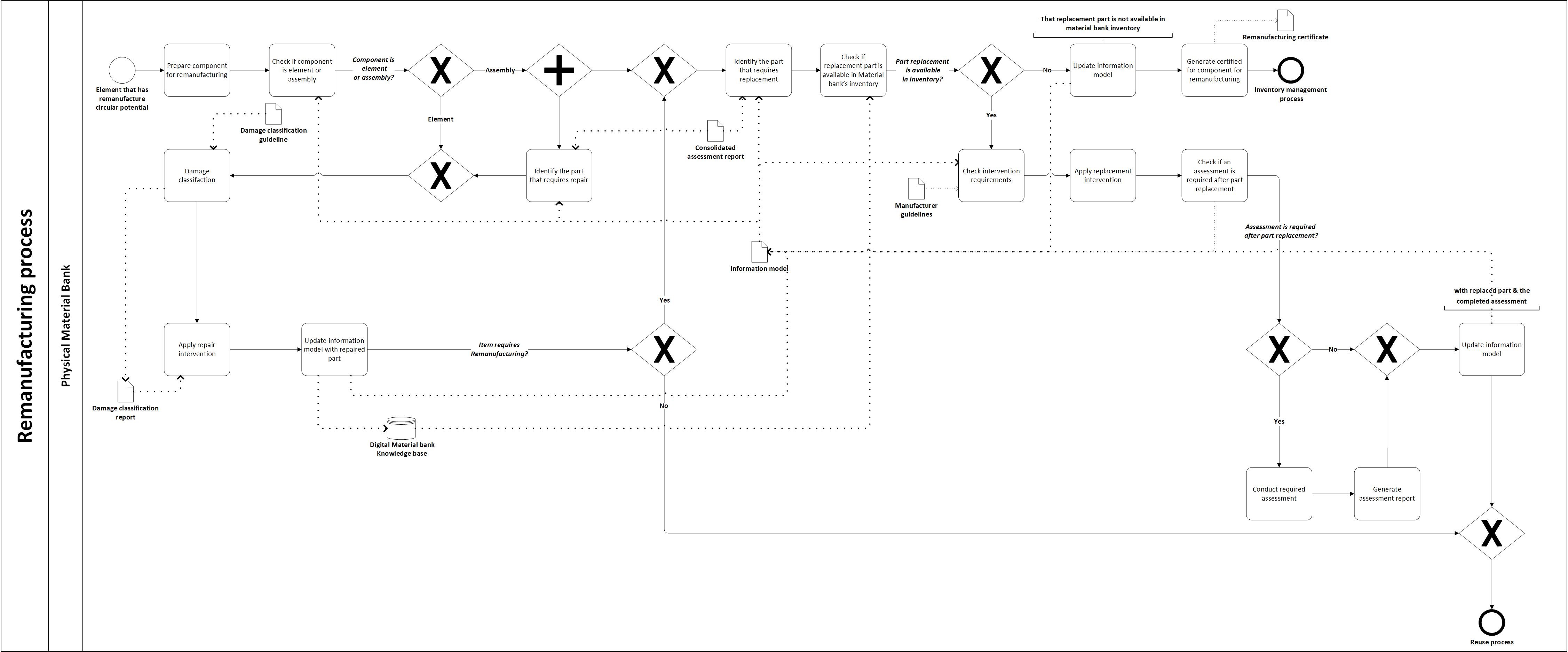

Figure 9 is the process map for Remanufacturing. Remanufacturing means that a product needs replacement of sub-parts or heavy refurbishment before it can be fully functional (or fully reusable). Therefore, if the material bank (or other responsible actors) decides that an item is not reusable but manufacturable, then the processes in the Figure 9 should be followed. Remanufacturing process involves several key steps. The first crucial task is to determine whether the component is an assembly. If it is, the next step is to assess if any sub-assemblies within it require repair. This involves a damage classification process that generates a damage classification report. Repair interventions are applied once the damage assessment is complete and the model or database is updated with the relevant information. One of the reasons that "Intervention Requirement" is modelled in the DOR taxonomy is to be able to enrich and exchange information about remanufacturing. If the repair process succeeds, the next step is to identify the parts within the assembly that need replacement. The material bank inventory is consulted to check if the required replacement parts are available. If they are, the identified parts are replaced accordingly, and intervention requirements are verified to ensure compliance. This remanufacturing process aims to refurbish and rejuvenate components, ensuring they are in optimal working condition for reuse.

Figure 9. Remanufacturing Process

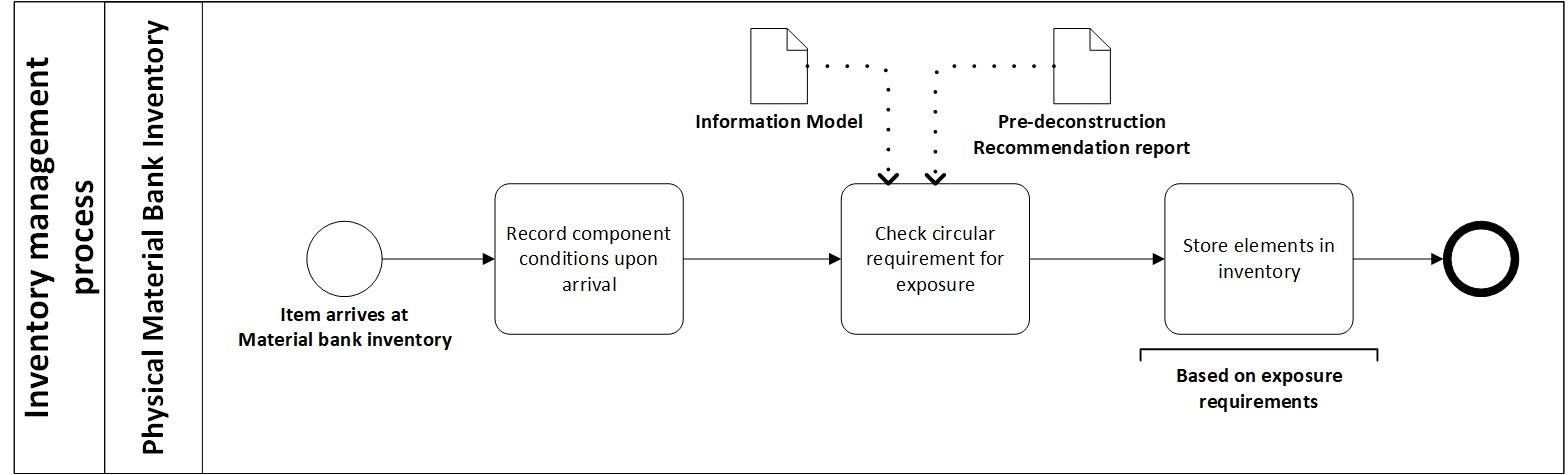

Figure 10 is Inventory Management Process. This occurs immediately after an element arrives at the material bank. Upon arrival, it may be necessary to (re)record the physical appearance and condition of the components (this is explained in Akbarieh et al. (2021)). Subsequently, the circular requirements for the components are digitally assessed. This includes determining the specific storage and exposure requirements based on the component's characteristics and the environmental conditions it can withstand without deterioration. Once the storage and exposure requirements have been established, the component is appropriately stored within the material bank's physical storage. This concludes the Inventory Management process, ensuring efficient management of components within the material bank.

Figure 10. Inventory Management Process

The elements are ready for reuse after assessing and recording the information about reclaimed pieces and recertification. The reuse happens through two actors: designers and contractors. However, two possibilities exist depending on the design process, as described below. It must be noted that "design with reusables" is a different process from "design for reuse.

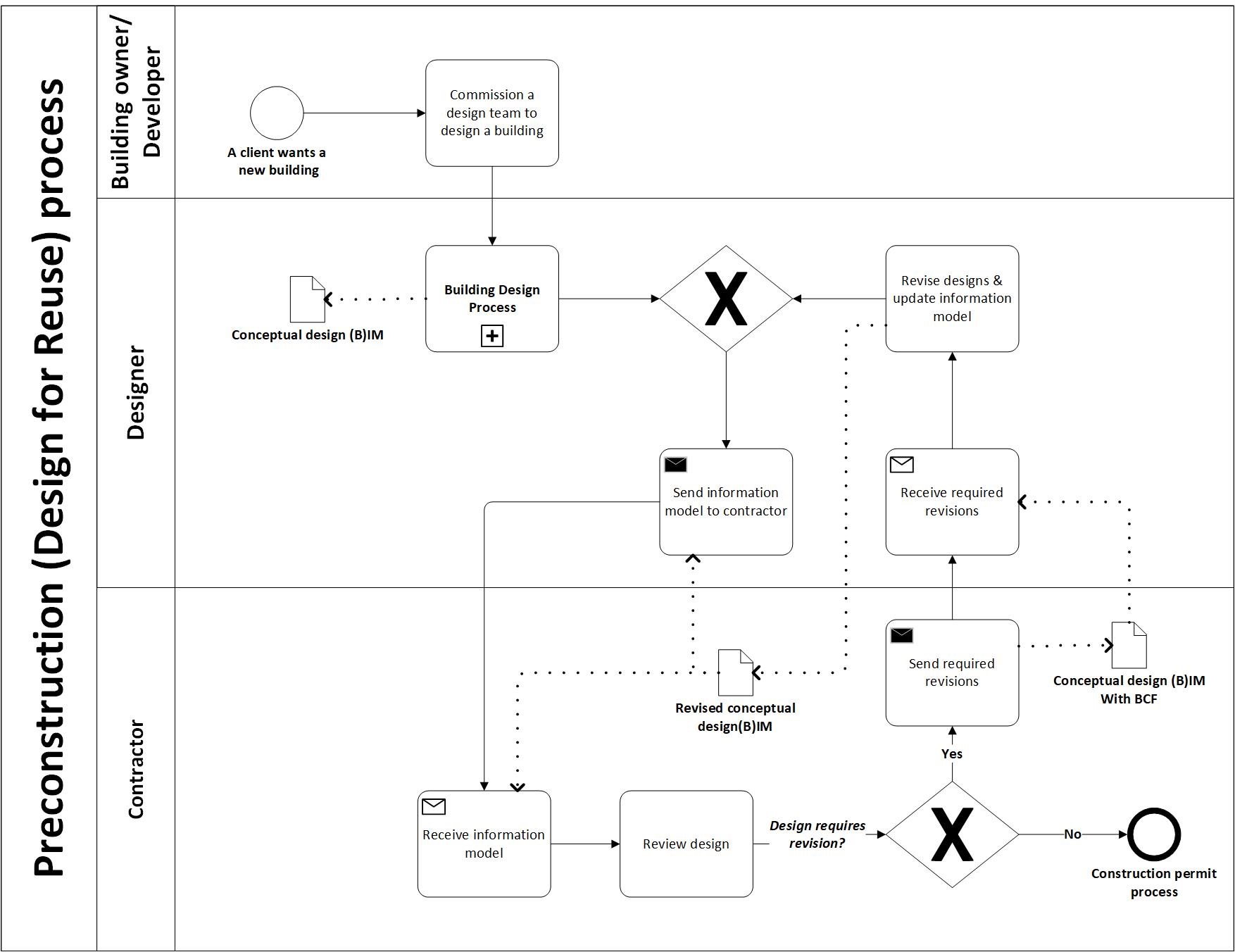

Figure 11 is the Pre-construction Process for Design for Reuse. This process involves three key stakeholders: building owners, designers, and contractors. The process begins when the building owner meets with the design team to commission the design for a new building. Once the designer is selected, they initiate the building design process and create a conceptual map based on the owner's requirements. The specific details of the building design process are explained separately in Figure G.10. After completing the building design activity, the information is communicated to the contractor. The contractor receives the information model and reviews the design. If necessary, they request revisions or modifications. Communication between the designer and contractor can be facilitated through the BCF. This collaborative review process continues until a successful design is achieved. The process concludes with obtaining a construction permit if no further changes or revisions are required, signifying that the design has been finalised and approved for construction.

Figure 11. Pre-construction Process - Design for Reuse

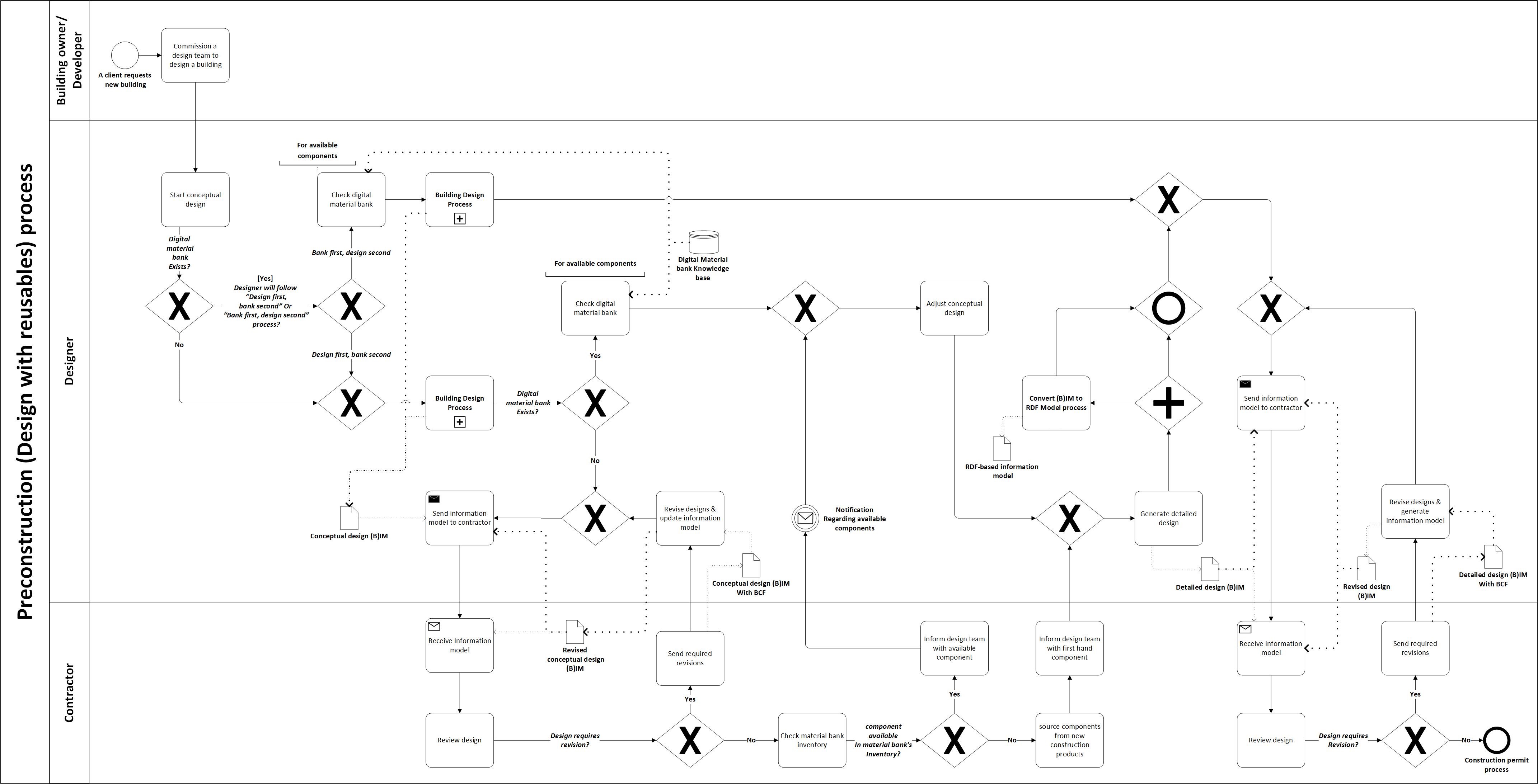

Figure 12 is the Pre-construction Process for Design with Reusable Elements. It illustrates the Pre-construction process essential when designing with reusable products/components/materials. This process differs from conventional design practices in the construction industry, where architects, engineers, and designers collaborate.

The process begins when a building owner/developer commissions a design team. The conceptual design phase starts with checking the availability of a digital material bank (or marketplace). If no digital material bank is available, the design needs to be adaptable to accommodate potential future support. The design team then proceeds with the building design process explained in Figure 13. They share the information model with the contractor, who reviews the design and checks if a material bank exists. They also evaluate the components available at that time within the material bank that meet the design. If suitable components are found, the design team is notified, and the conceptual design is adjusted accordingly. The detailed design is then communicated back to the contractor, and the procurement of second-hand, reusable products can take place. This process, referred to as "Design First, Bank Second," is further elaborated in Akbarieh et al. (2020). In other words, the design process happens first; then, the actors look for reusable elements. The alternative process, known as "Bank First, Design Second," starts from the exclusive gateway prior to the building design process activity. In this case, the designer must first check the digital material bank for available components. According to what is available in the reusable marketplace, the designer proceeds with the design. Information is exchanged between the digital material bank and the designers, and the building design process, as shown in Figure 12, is carried out. The design team then exchanges the final detailed model with the contractor. Afterwards, the contractor visits the physical material bank to purchase the digitally selected second-hand components. The design process with reusables concludes here with the contractor team applying for a building permit.

Figure 12. Pre-construction Process - Design with Reusable Elements

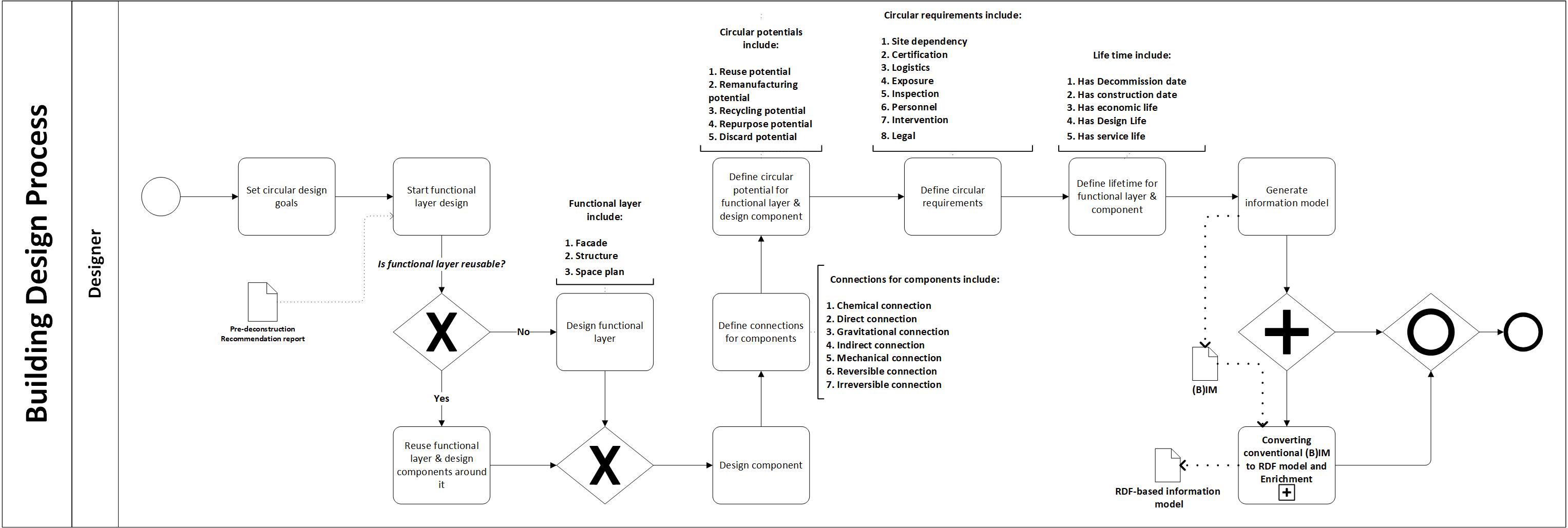

Figure 13 is the Building Design Process. It depicts the building design process, which begins with establishing circular design goals. The initial activity involves designing the functional layers, benefiting from the recommendations from the Pre-construction Recommendation Report if available. If there is a reusable functional layer on-site (which can be understood through the Site-Dependency Requirement), the design must be centred around it; in its absence, a new functional layer should be designed, followed by component and connection design. For each component or functional layer, circular potentials are determined in line with the initial circular design goals. Corresponding, circular requirements are then defined, considering factors such as age and lifespan. Once the preceding design steps are successfully completed, all the compiled information is generated as a single information model, including circular potentials and requirements for each potential, often resulting in a (B)IM.

Figure 13. Building Design process and using the DOR bSDD properties in different design decisions

The format-agnostic definitions referenced in the process maps above are presented in Table 1.

Table 1. Format-agnostic terminologies (encompassing both classes and properties) used for circular construction information requirement exchange

| Term | Description |

| Circular Potential |

To define what happens in the End-of-Life cycle of a building or functional layer or component, a circular potential can be attributed to it. Circular potential indicates a prospective end-of-life scenario for an object amongst all of the circular possibilities in the future. Newly designed objects are designed for a certain circular potential, for example, designed for reuse or designed for remanufacturing. Existing objects might need assessment to ascertain their circular potential. This class aims to standardise the subjective definitions of circular products and enable various circular definitions in a minimalistic approach. For example, an object already nested in the building that has a reusable potential is "reusable" even though its potential is not fulfilled - but it has the potential. Once the element is carefully removed from the building and reused in another project, it realises its circular potential and is "reused." In a scenario where testing is involved after the deconstruction of existing products, a marketplace or material bank can also use the "Circular Potential" to communicate new attributes following the assessment results. Therefore, the circular potential could be subjectively discussed by various agents and enable different circular definitions, all based on one property. In the examples above, different nuances of each product can be further elaborated and distinguished by using proper Circular Requirements, Reuse Counts and other properties available in this data dictionary. There are five circular potentials anticipated here: (1) Reuse Potential, (2) Remanufacturing Potential, (3) Recycling Potential, (4) Repurposing Potential, (5) Discard Potential. |

| Reuse Potential |

Reuse Potential is for components that need no major intervention (Aesthetic fixes might be necessary). If an assembly, all sub-parts of the assembly can be reused as they are deconstructed. If an element, the element as it is can be reused. |

| Remanufacturing Potential |

Remanufacturing Potential is second to Reuse Potential. If an assembly, some sub-parts of the assembly might need to be replaced or repaired before being reused in the next life cycle. If an element, the element needs major interventions such as repair before it can be reused. |

| Recycling Potential |

When an item can no longer be reused, remanufactured, or repaired, it can be recycled if the material is inherently recyclable. This results in the item having a Recycling Potential. For an assembly made with multiple materials to have Recycling Potential, each material must be recyclable. |

| Repurposing Potential |

For concrete, which is technically not recyclable, Repurposing Potential can be anticipated. |

| Discard Potential |

When an item can no longer be reused, remanufactured, repurposed or recycled, it will have Discard Potential. |

| Inspection |

An inspection might be a necessary requirement during or at the end of the life cycle for a component to reach its designated circular potential. |

| Material Source |

Material Source identifies the type of resources and material, e.g., renewable or hazardous. It emphasises the crucial role of the material's source in decision-making regarding reuse, EoL treatment, and handling. |

| Decommissioning Date |

The date when the building is scheduled or planned to be decommissioned. |

| Economic Life |

Economic Life refers to the amount of time an element is in service before it is more economically advantageous to decommission or replace it. The Economic Life can be used in cases where the exact service life or design life is not known, or if it does not match the expected service life of an existing building. The Economic Life is defined in years. |

| Design Life |

Design Life is considered as a useful period of lifetime where major modifications are not needed. The value of the Design Life is the specific number of years for which an object is designed to function effectively or remain operational. A reusable element can have one design life and multiple service lives, whereas a conventional element usually has the same design life as a service life. The Design Life is defined in years. |

| Total Reuse Count |

Total Reuse Count indicates the total number of reuses, i.e., reuse counts, that a product is designed for. The total reuse count reflects the maximum number of times a product is designed to be (re)used. Each (re)use cycle corresponds to the expected service life length, while the (re)use count corresponds to the number of cycles. In other words, total reuse counts correspond to the design life length divided by the expected life length. |

| Current Use Count |

Current Use Count represents the number of use counts that product is currently being used, from the total reuse count that the product is designed for. The current reuse count reflects the ongoing utilisation of the product compared to the total reuse count. |

| Connection Type |

A superclass that allows to describe the type of the connections. Different connection types facilitate different circular and End-of-Life possibilities, including: (1) Deconstruction, i.e., a building is taken apart into products; (2) Demounting, i.e., a product is taken out of a building; (3) Disassembling, i.e., a product is separated into components or sub-parts; (4) Dismantling, i.e., a product is separated into individual materials. The connection types, organised in alphabetical order, include Chemical Connection, Direct Connection, Indirect Connection, Irreversible Connection, Mechanical Connection, and Reversible Connection. |

| Personnel Requirement |

In the context of circular requirements, Personnel refers to the human resources (with or without particular qualifications or skills) needed to carry out specific tasks related to deconstruction, disassembly, reassembly, or other circular practices within a project. Personnel requirement includes Trained Personnel and Untrained Personnel. |

| Intervention Requirement |

Intervention Requirement is suggested for cases where a circular potential could be realised only after certain interventions are done. An intervention could be a minor or major modification after deconstruction, or an intervention during the life cycle. Similarly, this class can contain additional information when an intervention is of type of repair or replacement and so on. |

| Legal Requirement |

Legal requirement is a circular requirement that refers to the regulations, rules, and/or design and implementation standards that govern the treatment, handling, and reuse of components. By including legal requirements as part of the information models, stakeholders can ensure that the necessary legal considerations are observed. |

| Exposure Requirement |

Exposure requirement is a circular requirement that helps describe how a reusable item was (or should be) exposed to certain environmental conditions. If certain criteria must be met to keep the deconstructed elements in environmental conditions that prevent their deterioration, these could be described in this class. Moreover, detailing the storage conditions required to preserve reclaimed objects' quality and integrity could also be a part of this requirement. Elaborating Exposure requirements ensures that the reusable item maintains its functionality and longevity over time, thereby maximising its value and effectiveness. |

| Logistics Requirement |

Logistics requirements refer to the specific needs - such as packaging requirements, truck sizes, and other logistical considerations - related to the movement, transportation, and delivery of reusable components. |

| Certification Requirement | Certification requirements refer to the specific criteria or standards that need to be met in order to obtain certification for certain products, processes, or components within the context of circular economy practices. Not all circular potentials may require certification, but certification can be necessary for certain reusable structural parts or components. A certificate serves as a validation or endorsement that the product or component meets specific - or minimum - standards or specifications related to safety, quality, environmental impact, or other relevant criteria that makes it eligible to be re-introduced to the market. |

| Site Dependency |

Site Dependency requirement refers to the extent to which a construction project relies on the physical location of the current project. This circular requirement is important for decision makings in multiple layers and impacts the carbon and waste outputs of whether or not a component is reused on site or not. Site Dependency includes On-site and Off-site. |

| Primary Raw Resource |

A type of resource that is extracted from the planet and used as inputs for industrial production. They are not processed or altered and are used in the first life cycle stage in the creation of a finished product. |

| Secondary Raw Resource |

A type of resource that is recovered from previous use or is recovered waste originating from another product system and utilised as an input in another product system. Often, secondary raw material sources are recycled ones. |

| Recyclable Resource |

A type of resource that has the natural characteristics to be diverted from the waste stream thanks to available recycling processes and programmes. Once collected, they undergo processing to return to the value chain and further (re)use, often as raw materials for manufacturing or production. |

| Renewable Resource |

A type of resource that can be grown, harvested and naturally replenished or cleansed on a human time scale. |

| Hazardous Resource |

According to the Waste Directive 2008/98/EC, hazardous materials are sourced from the type of resources that will cause health damage to humans, animals, plants, living organisms, and the environment. |

| Waste Code |

Represents the waste code associated with the material, as per waste management classification systems, for instance, the European Waste Code (EWC). |