- Aucun résultat trouvé

- Cas d'utilisation

- Co-Creation Space

Communauté

Organisations

Partenaires de collaboration

- Connexion

PAS ENCORE INSCRIT?

Inscrivez-vous au Service de Gestion des Cas d'Utilisation gratuitement pour commencer à créer votre premier cas d'utilisation.

Les utilisateurs inscrits peuvent utiliser la zone de téléchargement et les fonctions de commentaire.

All dokuments are licensed as a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License

(Attribution-Non-Commercial-ShareAlike 4.0). Further information can be found at

![]()

The documents reflect the current best practice and do not claim to be complete. They should not to be understood in the sense of a generally valid recommendation or guideline from a legal point of view. The documents are intended to support appointing and appointed parties in the application of the BIM method. The documents must be adapted to the specific project requirements in each case. The examples listed do not claim to be complete. Its information is based on findings from practical experience and is accordingly to be understood as best practice and not universally applicable. Since we are in a phase in which definitions are only emerging, the publisher cannot guarantee the correctness of individual contents.

Across Europe, there is a real and urgent demand for deep renovation of the existing building stock and transformation of vacant, obsolete, or vacant buildings into dwellings. Due to the enormous scale of such operations and the need for the attainment of energy efficiency goals, a systematic approach is required to inform any decision-making in the process of renovation with respect to the monetary and environmental consequences of the choices. However, several challenges must be overcome prior to scaling up the renovation process resulting in energy-efficient buildings. One of the challenges is the lack of tools and methods for quickly estimating the costs, benefits, and expected return on investments for each proposed renovation strategy at an early stage of decision-making. As detailed in Directive 2014/24/EU of the 2014 to identify the most advantageous tender, the decision should not be only based on non-cost criteria. Qualitative criteria should therefore be accompanied by a cost-effectiveness approach such as life-cycle costing. Simple “payback time” is a quick way of evaluating the financial attractiveness of EE measures and sufficient evidence-based information on the costs and benefits (Liu, Meyer, and Hogan 2010). The main purpose for developing this use case is to propose a systematic and quick Life Cycle Costing (LCC) calculation to be able to compare different renovation strategies.

Aim: The “LCC tool” was developed to:

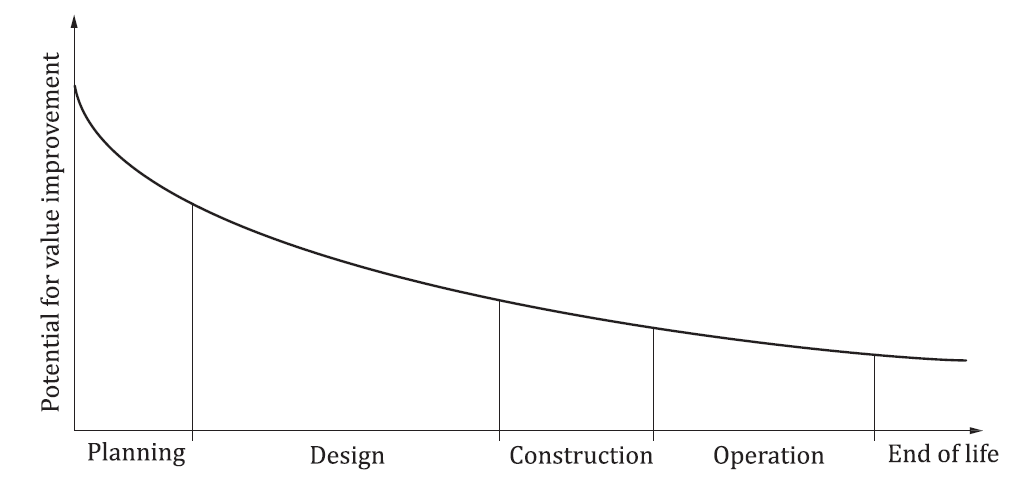

Scope: In principle, the LCC analysis can be applied to different stages of the life cycle of an asset, however, as shown in Figure 1, the potential for value improvement is much greater in the planning stage compared to other stages. Up to 80% of the operation, maintenance, and replacement costs of a building can be influenced by the first 20% of the design and planning process.

The LCC analysis normally gives insight into the following questions:

Figure 1: Different scopes and the extent to which they influence LCC savings over time based on NEN-ISO 15686-5

The objectives for the use of the LCC tool may include time reduction and consequently, cost reduction as well as improved accuracy of calculating the financial performance (KPI) of a renovation scenario.

Future improvement:

The BIM model is currently enriched according to project specifications, although the values used are fully compliant with existing NL/SfB and NE2767-2 standards (‘BIM Loket - NL/SfB’ n.d.). Mapping of NL/SfB onto IFC and vice versa are, however, active areas of research. Developments in this domain could further enhance the efficacy of the BIM-based LCC. Additionally, since LCC calculation requires assumptions about future behaviour, sensitivity analysis (such as Monte Carlo analysis) can be added to allow for the identification of a distribution of possible costs and a range of more and less probable figures for use in calculations.

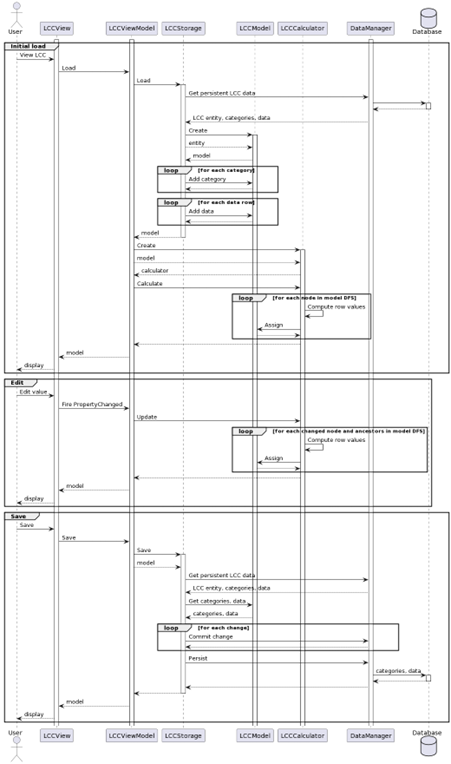

Figure 2: UML Sequence diagram of interaction between LCC tool components

All LCC functionalities are integrated into the RE Suite. The tool can be accessed with any web browser by visiting https://demo.demobv.nl and logging in using provided credentials.

The calculation requires a different category of costs based on the scope and level of analysis for each project. This can be specified in the tool and a user can tailor their calculation by adding/deleting rows. The cost items are mainly divided between Capital Expenses and Operational Expenses. In principle the LCC table has the following columns to fill out:

Description, a recognizable name for the line item in the LCC

Quantity, an optional field that can be used to compute the Cost

Unit cost, an optional field that can be used to compute the Cost

Cost, which can be automatically computed as Quantity * Unit Cost if both are filled or manually filled out otherwise

Start year, the first year the expense occurs

Cycle, how often the expense reoccurs, e.g., every 3 years

Duration, after how long the expense stops reoccurring, e.g., after 10 years

A bidirectional connection between the BIMSpeed platform and the RE Suite has been established. Users can navigate between the two platforms, and exchange data between them. When a user is on the BIMSpeed platform, it is possible to reach the RE Suite through the User Interface of the BIMSpeed platform. There are two ways to do this:

1 - Through External Services: RE Suite is always accessible through ‘External Services‘, which can be reached by clicking the External Services button on the top of any project homepage. If the user clicks on ‘Go to the service’, the service is triggered.

2 - Through IFC’s: RE Suite is registered as a service relevant for IFC files. Any IFC file on the BIMSpeed platform can be directly opened in RE Suite by clicking on the ‘3 dots’ menu of the IFC file, selecting ‘Access to services’, and clicking on ‘Go to the service’. In the background the webservice of RE Suite is called. After successful login the file is automatically downloaded and shown in the RE Suite 3D viewer. From here multiple BIM related applications are available.

Demonstration:

One of the BIM-Speed project demonstration cases pertains to four three-story residential apartment blocks in Warmond, The Netherlands. Constructed in 1969, these complexes are owned and managed by the social housing corporation Stek. The apartments are positioned above a semi-sunken basement where people find their own personal storage rooms.

Within the BIM-Speed project renovation options for these complexes are considered, such as:

The BIM-Speed LCC tool is applied as proof of concept to one of the complexes to gain insight into the financial impact of the renovation options in both expenses and returns.

Figure 3: demonstration case in Warmond, The Netherlands

For the purpose of demonstrating the LCC tool, the BIM model had to be enriched with additional information, needed to perform the LCC analysis. Besides the geometrical information of elements, which can easily be read from the BIM model, it was also required to have information about the material and element description, following the NEN2767 and NLSfB standards. The goal was to add 5 new parameters to the elements, which are going to be included in the renovation process, namely the:

Additionally, it was desired to have a parameter which will specify whether the element is going to be renovated or not, so the 6th parameter was added, and that is:

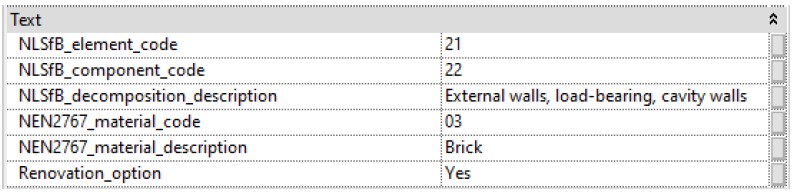

An example of an external wall with cavities, which is made of bricks, is going to be renovated and has the following classifications

the parameters would be filled as follows:

Table 1: Example of parameters and values

Implementation

The implementation of enriching the BIM model was performed in Autodesk Revit software. The first step was to define six new project parameters. The type of parameters was defined as “Text” and they were grouped under the section “Text”. Parameters were assigned to Floors, Roofs, Walls, and Windows, as these are the categories which are going to be included in the renovation scenarios. An example of the definition of the parameter “NEN2767_material_code” can be seen in Figure 4.

Figure 4 Definition of one of the parameters

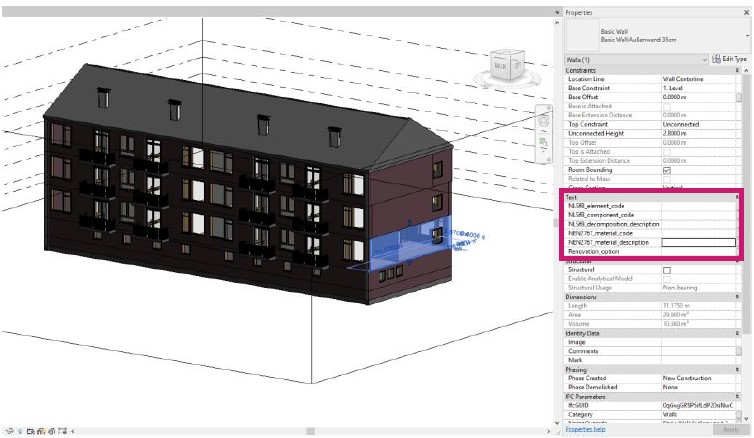

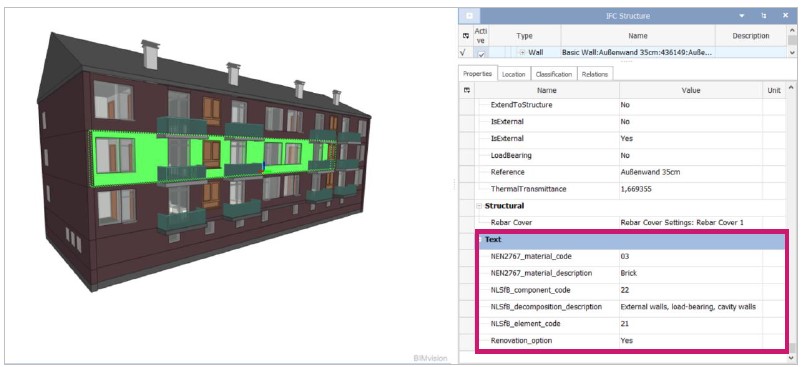

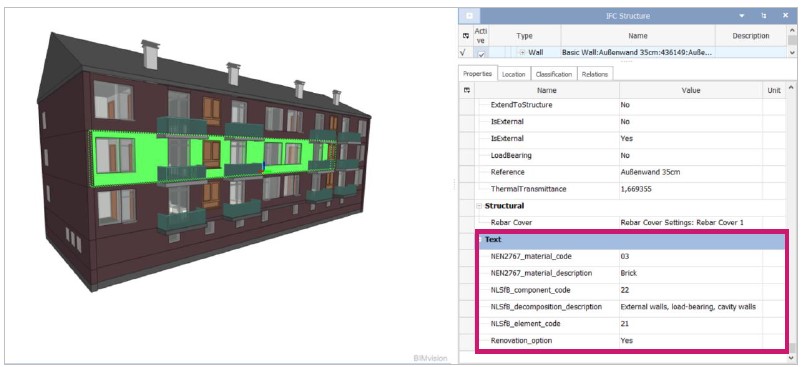

By clicking on one of the elements, to which the parameters were assigned, the new parameters can be visible under the Properties section. They are located under the group “Text” as exhibited in Figure 5.

Figure 5 Newly defined parameters

For each element in question, the new parameters had to be filled in with values, as seen in Figure 6 for an example of an external wall.

Figure 6 Parameters with values

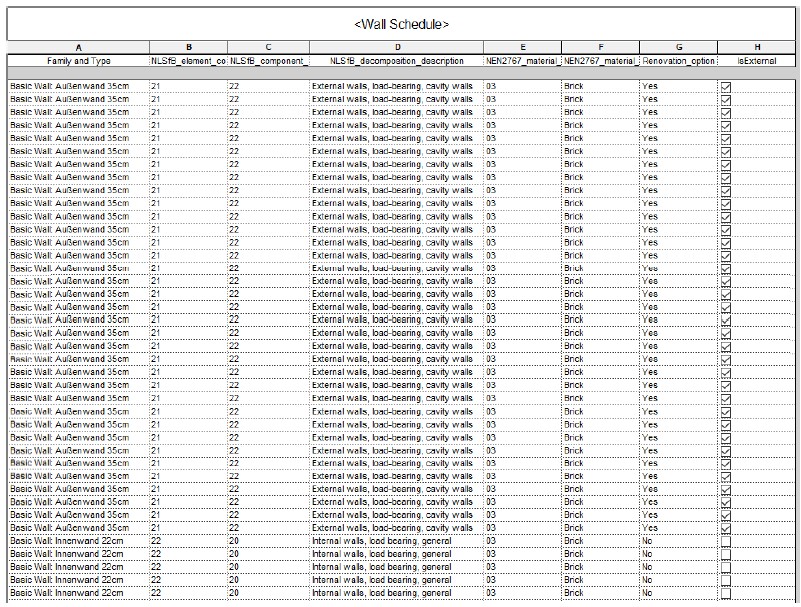

To better monitor the process of filling in the values, a schedule was created, which offered an overview of all the elements from a category. This way no element was left out. From a wall schedule in Figure 7 it can be seen how values were entered for each element. Additionally, adding the parameter “IsExternal” to the list was helpful to differentiate the internal walls, which are not included in the renovation, from the external wall, which are included in the renovation and therefore have “Yes” as a value for the “Renovation_option” parameter.

Figure 7 Wall schedule

The same process was repeated for the windows, floors, and roof. The below table includes all the different parameter values which were used in the model.

Table 2 Parameter values

Once the model was enriched with the information, needed for the LCC analysis, it could be exported as an IFC file. When choosing “Export Revit property sets” as an export option, the newly defined parameters will be exported, but they will be grouped under “Text” as seen in Figure 8, where BIMvision software was used as an IFC viewer.

Figure 8 IFC model with “Export Revit property sets” settings

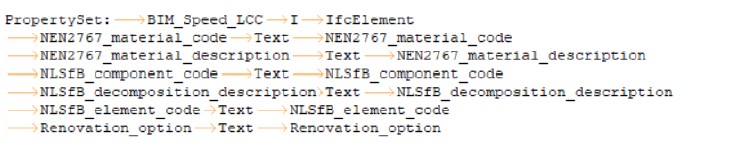

Since it was desired that the group of parameters, which is now called “Text” would be associated with the BIM Speed LCC, a User Defined Property Set had to be first composed, to be used as export options. This was done with a TXT file, which includes instructions for the Property set naming. The TXT file specifies, that the property set name is going to be “BIM_Speed_LCC” and that it will apply to Instances and to every IfcElement. After that, the parameters are listed, together with their Data type and their Revit parameter name. The TXT file can be seen in Figure 9.

Figure 9 TXT file for User Defined parameters

This TXT file was used in the IFC export settings, under the tab Property Sets, where “Export user-defined property sets” was selected with a tick and by clicking on the Browse button, the TXT file was selected as shown in Figure 10.

Figure 10 IFC export options

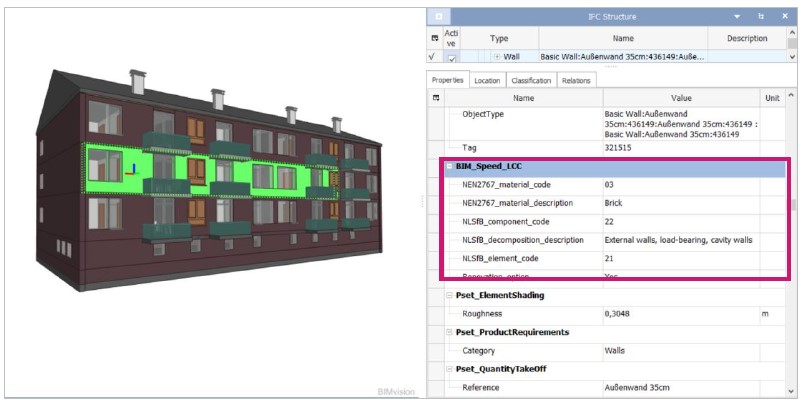

With these settings, the newly defined parameters are now grouped under “BIM_Speed_LCC” as seen from the IFC viewer in Figure 11.

Figure 11 IFC model with “Export user-defined property sets” settings

Scenario comparison

To evaluate the efficacy of the BIM-based LCC two renovation options are considered for the complex Woudestraat in Warmond, The Netherlands. The renovation concerns applying façade cladding with thermos-acoustic insulation panels. The type of material is in question.

For the purposes of this proof of concept, the financial impact of installation and materials are offset against subsidy and reduced energy costs.

The complex has a BIM model available, and it is enriched as described in chapter 1.1, denoting building decomposition and material specifications as well as which elements are relevant for renovation.

These relevant elements are imported into the LCC Tool as described in chapter Error! Reference source not found.. This results in generally available building information.

For each strategy, an LCC is created and pre-filled with default categorization as depicted in Error! Reference source not found. The LCCs are now filled out with details regarding the specific scenarios.

The quantity of the elements marked for renovation can be imported from the BIM model.

The main difference in cost is the choice of insulation panel. By specifying the product name in the LCC and importing unit costs from the BIM-Speed Catalog the total financial impact is immediately calculated.

Upon estimating the reduction in heating costs this yields a cumulative total life cycle costing graph for the two strategies as depicted in Figure 12. As can be seen, while the initial outlay for a more thermally isolation material is higher, the costs are eventually recaptured due to reduced heating costs.

Figure 12: Strategy comparison for different isolation materials. The red line depicts a strategy with more thermal isolation

To compare how the strategies respond to different scenarios the inflation, interest, and income index parameters can be adjusted. If one of the strategies is only viable in a narrow range of scenario parameters, it can be considered high risk.

The figure above provides an indication of the scope for LCC savings that can be made during the project lifecycle

phases.

NOTE 1 The planning and design phase offers the greatest potential to influence the post-construction lifecycle

cost, since the opportunity to influence the design and construction becomes increasingly limited as the

acquisition phase proceeds beyond the commitment to invest in purchase or construction of the asset. Up to

80 % of the operation, maintenance and replacement costs of a building can be influenced in the first 20 % of the

design process.

Decisions, data feedback and continual monitoring and optimization of LCC should continue through

the service life of the facility.

In order to achieve the benefits possible from the planning and design stages, the original life-cycle

costing assumptions shall be reviewed and progressively refined or replaced by better analysis of quantities, costs and predicted performance. Assumptions about the basis of calculation (such as the

period of analysis and the discount rate to be applied) shall also be confirmed during this phase of the

analysis.

NOTE 2 As the design is developed, the LCC plan is estimated from the capital and operational cost plans,

based on the level of information available.

The LCC analyses should be developed concurrently with the design and should be continuously related

back to the initial plan, with any conflicts highlighted and resolved as applicable. Progressively, reliance

on historic costs should be replaced by confidence in predicted costs for the project under review.