- Aucun résultat trouvé

- Cas d'utilisation

- Co-Creation Space

Communauté

Organisations

Partenaires de collaboration

- Connexion

PAS ENCORE INSCRIT?

Inscrivez-vous au Service de Gestion des Cas d'Utilisation gratuitement pour commencer à créer votre premier cas d'utilisation.

Les utilisateurs inscrits peuvent utiliser la zone de téléchargement et les fonctions de commentaire.

The documents are licensed as "Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License" as Attribution - non-commercial distribution - under the same conditions

For further information see: creativecommons

The documents do not claim to be complete. Nor are they to be understood in the sense of a recommendation or guideline that is generally valid from a legal point of view, but are intended to support the client and contractor in applying the BIM method. The use cases must be adapted to the specific project requirements. The examples given here do not claim to be complete. Information is based on practical experience and should therefore be regarded as best practice and not generally applicable. As we are in a phase in which definitions are only just emerging, the publisher cannot guarantee the accuracy of individual contents.

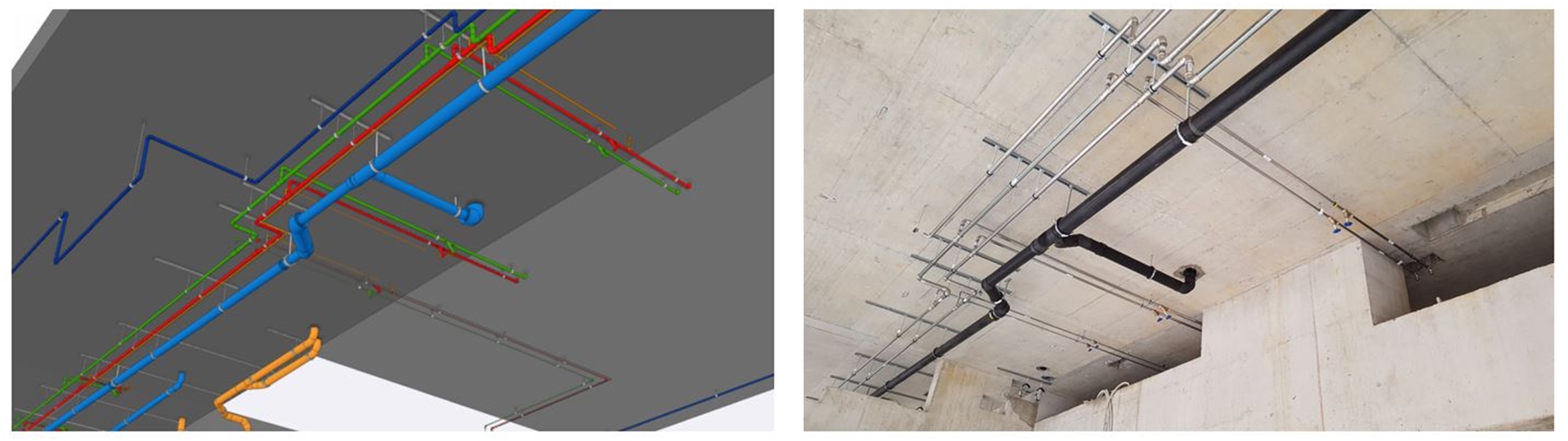

The benefits of industrial prefabrication of plumbing and heating pipes include:

Description of the requirements for industrial prefabrication of plumbing and heating pipes. The core of the method is the ‘z-dimension’ and an associated uniform measuring procedure. This long-established procedure is now described in such a way that it can be used in digital building models with the BIM method. The modelling done as part of the work preparation utilises geometric templates. All pipes are delivered prefabricated in accordance with the building project specifications. This enables significant efficiency gains in the assembly process and markedly simplifies the installer’s work at the construction site.

This use case has the following objectives:

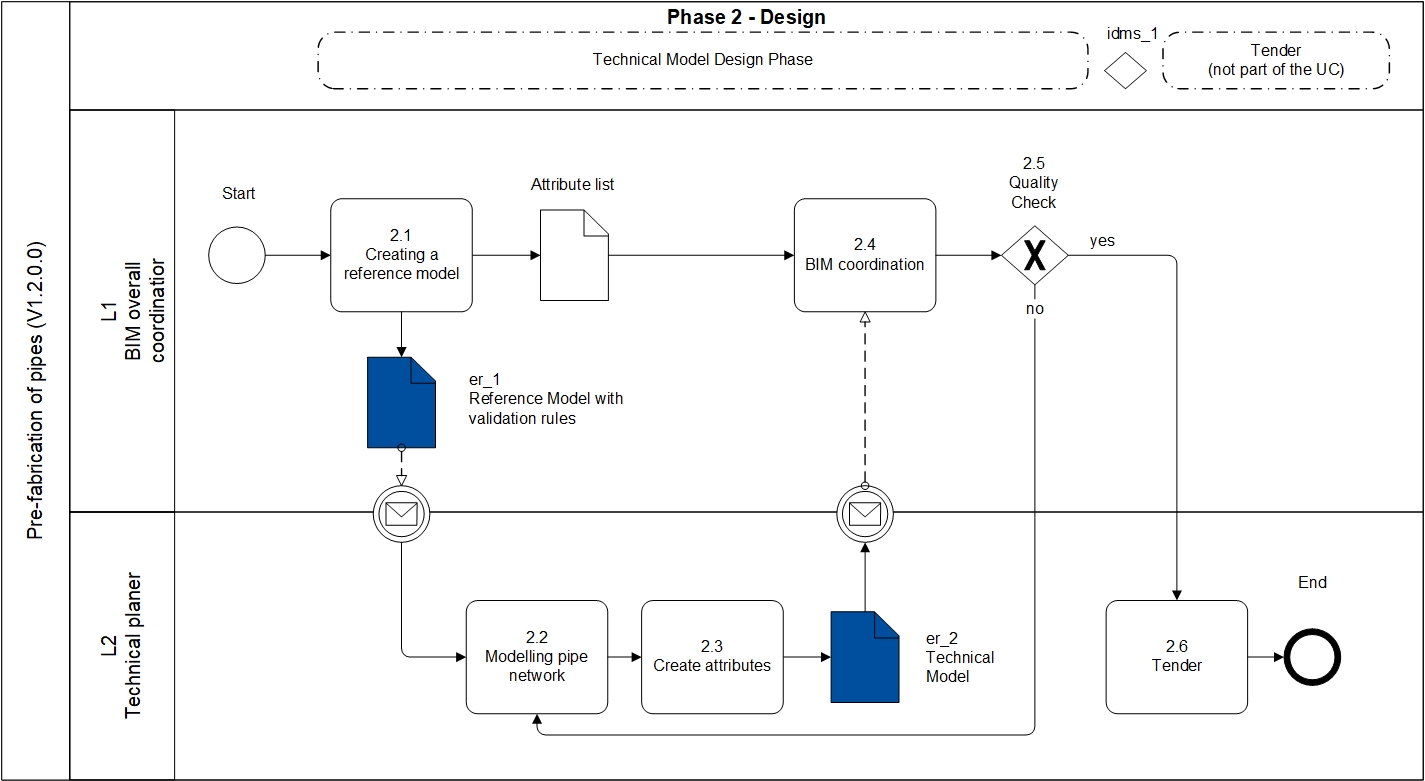

The BIM overall coordinator provides the reference model. In most cases, this is the architecture model.

Validation rules

The validation rules define the specifications for validating whether the defined pipe networks are correctly modelled and the attributes correctly enriched in accordance with the information request.

Initiator: BIM Overall Coordinator

The BIM overall coordinator provides the specialist planner with the agreed modelling guidelines.

Architectural Model (LOG 200)

Optional: Specialist model(s) of other building technology disciplines (LOG 200)

The following attributes are provided for in terms of modeling guidelines in project planning:

modeling guideline

modeling guideline with attribute list for reference model

Initiator: BIM Overall Coordinator

Executer: Technical Planner

The building technology model author models the existing pipe networks in the project. This could include:

Contiguous parametric pipe networks are to be planned in the models.

Initiator: Technical Planner

Enriching the model components using the attribute list in the information request

Initiator: Technical Planner

The attributes have been imported into the project plan according to the information request.

Specialist model(s) of other building technology disciplines (LOG 200)

attributes

The following attributes are provided for in terms of modeling guidelines in project planning:

Initiator: Technical Planner

Executer: BIM Overall Coordinator

Coordination of the individual technical and component models of BIM projects with multiple disciplines or companies. This includes the merging of digital building models into coordination models as well as the formal and functional evaluation of the digital building models using predetermined rules. This must be done on the overall direction level and can be supplemented by the BIM coordination within individual technical disciplines.

Initiator: BIM Overall Coordinator

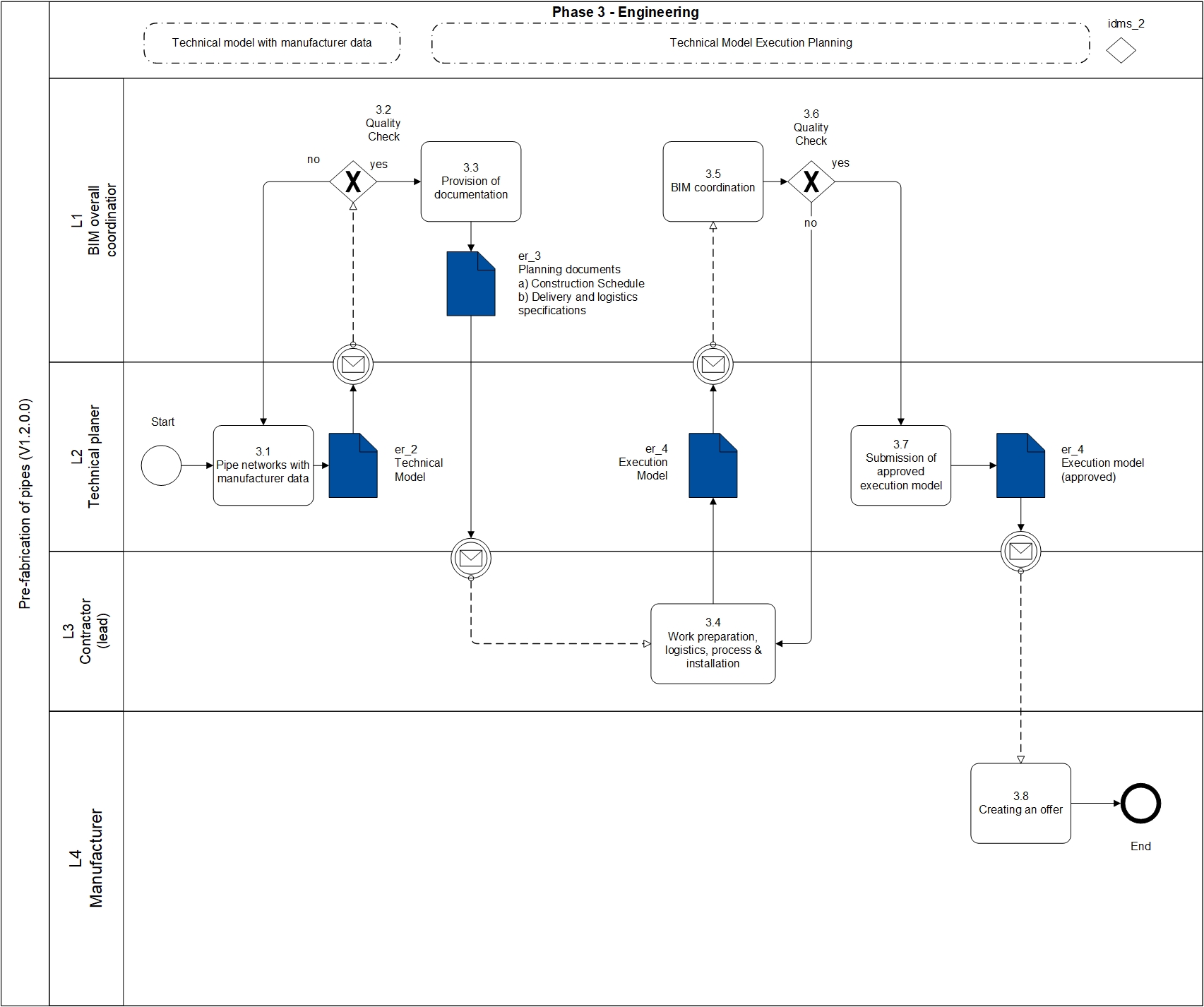

Enriching the pipe network with manufacturer data

Initiator: Technical Planner

er_2 from design phase additionally with the selected manufacturer and pipe system

Specialist model(s) of other building technology disciplines (LOG 200)

The following attributes are included in the execution plan:

Initiator: Technical Planner

Executer: BIM Overall Coordinator

Decision whether the model quality is sufficient for the defined requirements. If the quality is insufficient, a revision must be commissioned. If the quality requirements are fulfilled, the model is provided to the technical planner for further processing.

Initiator: BIM Overall Coordinator

Provision of the construction schedule as well as delivery and logistics specifications

Initiator: BIM Overall Coordinator

Provision of the following documents

Construction schedule

The construction schedule must include the following information:

Delivery and logistics specifications

The delivery and logistics specifications must contain the following information:

Initiator: BIM Overall Coordinator

Executer: Contractor (lead)

In the work planning process, the contractor processes the model such that it can be prefabricated for construction in the required work cycles. The information request and construction schedule are required for this.

Initiator: Contractor (lead)

The contractor places the order with the manufacturer or supplier.

Initiator: Contractor (lead)

Like er_3 but with additional data

Specialist model(s) of other building technology disciplines (LOG 200)

The delivery and logistics requirements must receive the following information:

Initiator: Contractor (lead)

Executer: Manufacturer

The manufacturer segments the information for planning the prefabrication process. This includes price calculation, cutaway planning, final length calculation, delivery lots, etc.

Initiator: Manufacturer

Decision whether the technical models will be supplemented with information from the supplier / manufacturer

Initiator: Manufacturer

The manufacturer or supplier optionally adds request information.

Initiator: Manufacturer

Like er_4 with additional data

Specialist model(s) of other building technology disciplines (LOG 200)

The following attributes are included in the execution plan:

Initiator: Technical Planner

Executer: Manufacturer, supplier or contractor (if built independently)

Decision whether the model quality is sufficient for the defined requirements. If the quality is insufficient, a revision must be commissioned. If the quality requirements are fulfilled, the model is provided to the technical planner for further processing.

Initiator: BIM Overall Coordinator

If the technical models are available in the desired model quality and the attribute list is complete, the model can be used to create the tender.

Initiator: Technical Planner

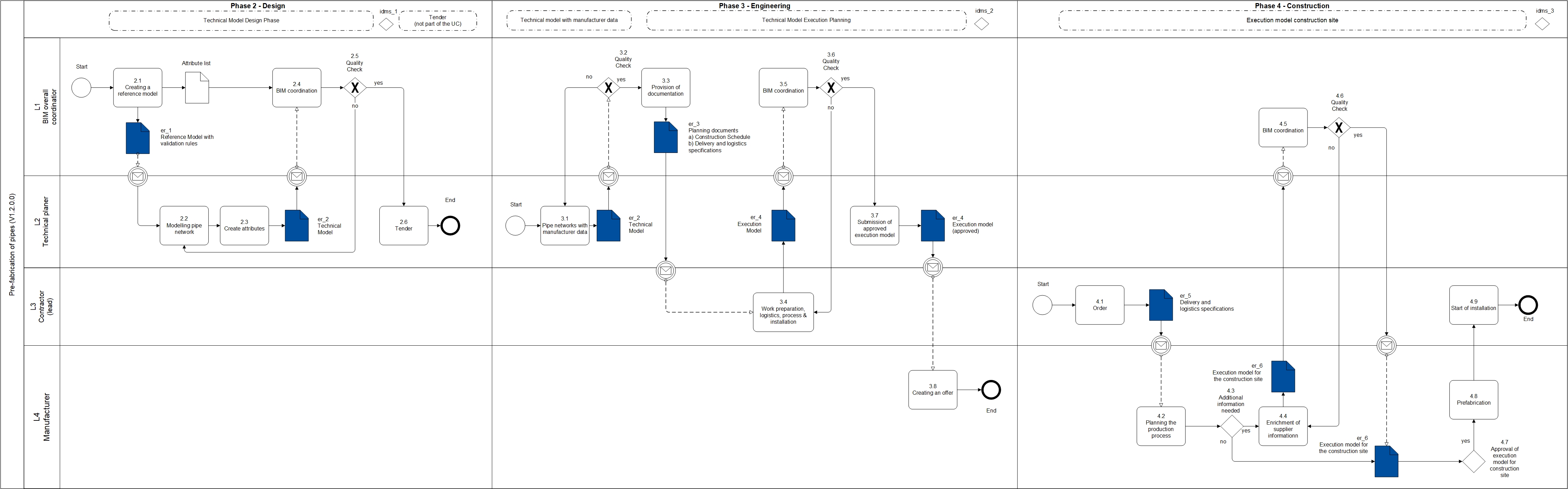

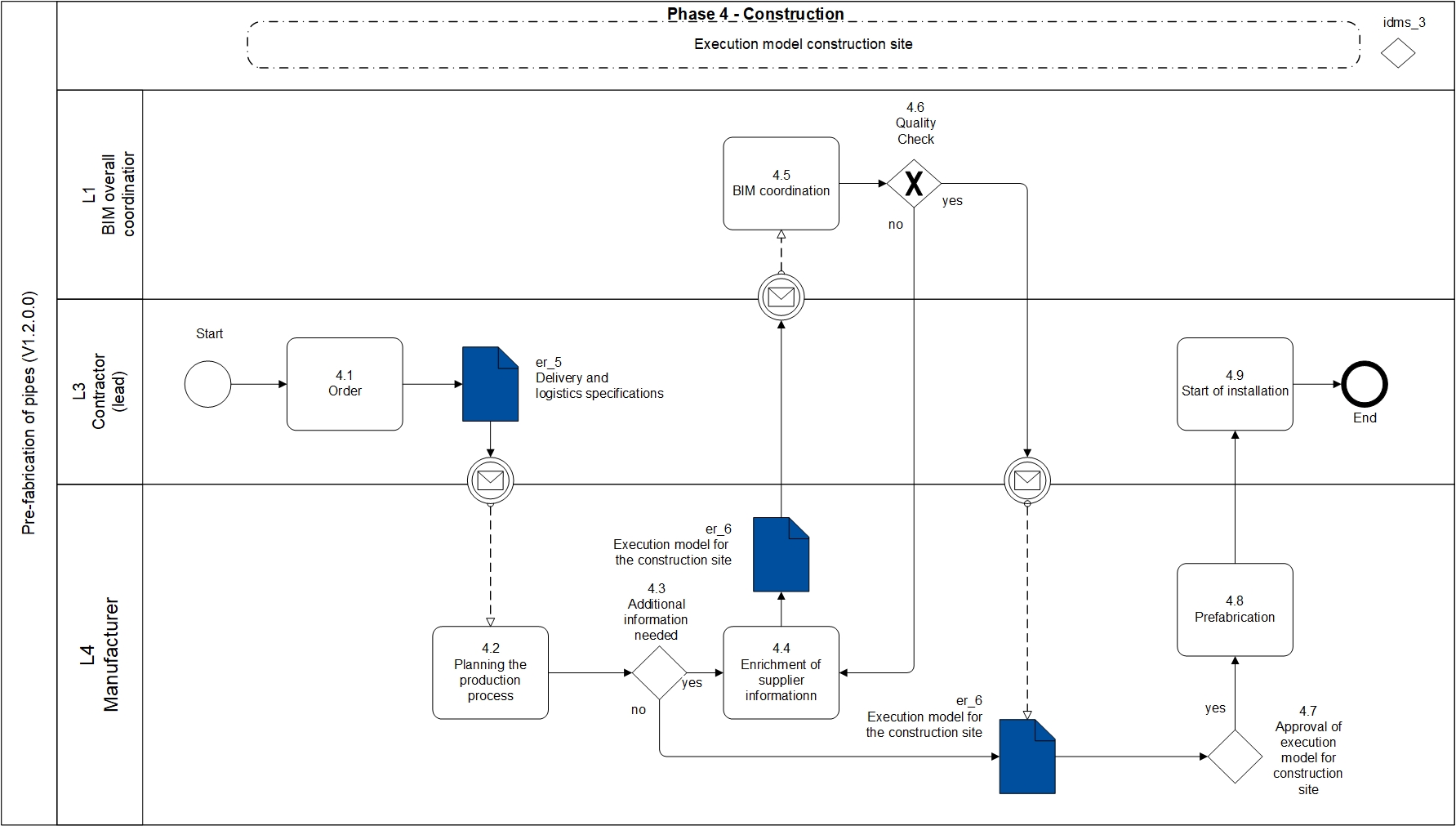

The Information Delivery Milestone consists of the following business processes and information exchange requirements:

Specialist Model Project Planning

Like er_2 but with additional data

Specialist model(s) of other building technology disciplines (LOG 200)

The following attributes are provided for in execution planning:

Initiator: Contractor (lead)

Executer: BIM Overall Coordinator

Coordination of the individual technical and component models of BIM projects with multiple disciplines or companies. This includes the merging of digital building models into coordination models as well as the formal and functional evaluation of the digital building models using predetermined rules. This must be done on the overall direction level and can be supplemented by the BIM coordination within individual technical disciplines.

Initiator: BIM Overall Coordinator

Decision whether the model quality is sufficient for the defined requirements. If the quality is insufficient, a revision must be commissioned. If the quality requirements are fulfilled, the model is provided to the technical planner for further processing.

Initiator: BIM Overall Coordinator

The approved execution model is transmitted to the manufacturer.

Supported formats:

Initiator: Technical Planner

Based on the approved execution model, the manufacturer creates an offer

Initiator: Manufacturer

The Information Delivery Milestone consists of the following business processes and information exchange requirements:

Specialist model with manufacturer data

Technical Model Execution Planning

Coordination of the individual technical and component models of BIM projects with multiple disciplines or companies. This includes the merging of digital building models into coordination models as well as the formal and functional evaluation of the digital building models using predetermined rules. This must be done on the overall direction level and can be supplemented by the BIM coordination within individual technical disciplines.

Initiator: BIM Overall Coordinator

Decision whether the model quality is sufficient for the defined requirements. If the quality is insufficient, a revision must be commissioned. If the quality requirements are fulfilled, the model is provided to the technical planner for further processing.

Initiator: BIM Overall Coordinator

Decision whether the execution model for production or installation at the construction site is approved

Initiator: Manufacturer

The pipes are prefabricated according to specifications. This process step can be done at the contractor’s or the manufacturer’s / supplier’s location

Initiator: Manufacturer

Pipes are installed at the construction site according to the numbering logic

Initiator: Contractor (lead)

The Information Delivery Milestone consists of the following business processes and information exchange requirements:

Execution Model Project Planning